Building a Very Stout, But Affordable, Weekend Driver

Time and time again, our advice to those interested in learning about stout-running engines is that it’s the total combination that makes it all happen—considering, of course, that components are prepped, cleaned and assembled as if in a “clean room.”

Also, we know that physically there are great working combinations, and any 383 crate engine would be at the top of the small-block list. The low-rpm torque and great upper-rpm horsepower are the characteristics most likely from this combination, but they, too, can be improved upon, depending upon cam selection, cylinder head choice and induction used. If you don’t mind a lumpier idle, and high vacuum at idle is not an issue, then installing more cam timing will add to the overall power curve–but again, it’s all in the combination.

5 to 7 more horsepower.

While discussing the value of the 383 at Joe Sherman Racing Engine Development in Santa Ana, California, the broad subject of 383 stroker motor combinations was tabled in earnest. What about a 383 with a more radical camshaft and, say, a 6,200-rpm rev limit? What would be the better heads for a street application as opposed to an all-out racing combo? Which is the proper compression ratio, and what are the proper lower-end reciprocal choices, like the oil pan and its capacity, the intake and carburetor choice, the ignition and–when all this has been chosen–the camshaft? And, when all is said and done, what would the real-world power production be, and would such an engine be affordable?

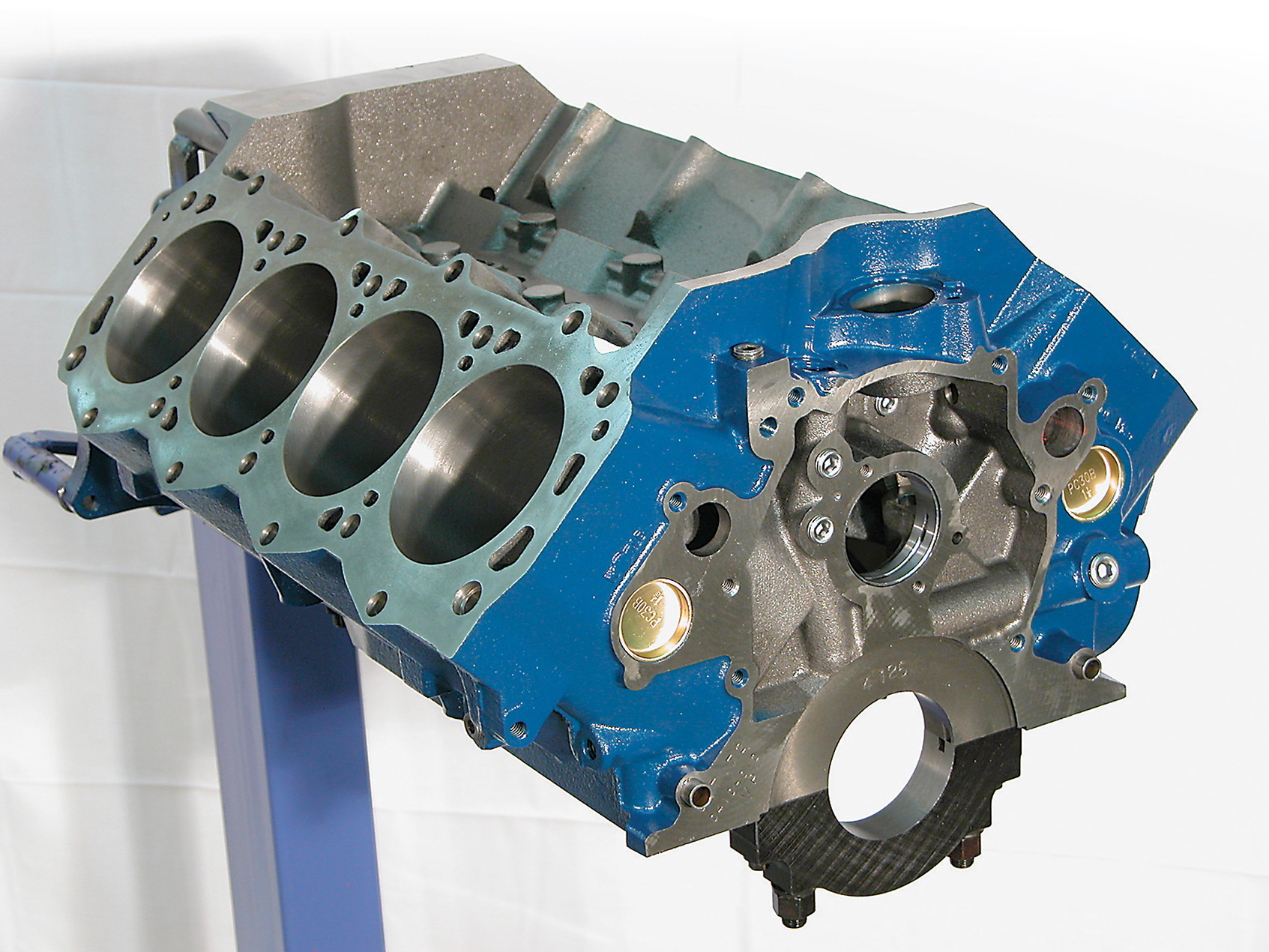

As these topics were being discussed, we ran it all by Joe Sherman in the form of another question: What would make up such an optimum engine, and is there such a thing? His reply was typical Sherman: “I’ve been tweaking on the notion of building just such a weekend 383, using a 350 block, thinking that 10.25 to 10.5:1 compression–using the new Racing Head Service cast-iron heads, a cam with a radical idle most guys want, a 750cfm single four-barrel carb–would easily produce over 500 hp at a reasonable 6,000 rpm, and above all more than 500 lb-ft of torque. And I think such a 383 could get the job done using heads with the 1.94-inch intake valves, rather than the larger 2.02 inches, and a hydraulic roller camshaft.” Who are we to argue? We simply said, “Do it!”

We understood where he was coming from and where he intended to go, and it was right up our alley. Sherman’s years of building and testing small-block Chevy parts has taught him a thing or two about what parts are capable of producing power, and how much. He’s built a lot of engines, made untold number of dyno runs, and seen his engines in customers’ cars at the dragstrip, circle track and on the water. So, we understood that when we heard the man say “his” 383, using 91-octane pump gas, with a corresponding compression ratio, street-ported iron heads and store-bought everything else, would produce 500 hp, our thoughts turned to the camshaft–the very heart of making such a combination perform as designed.

Sherman’s plan is to incorporate a Competition Cams hydraulic roller, ground on 106-degree lobe centers. That’s basically all he would say about the cam; he offered no valve lift or duration information, as if a flip through the Comp catalog couldn’t come up with something close that would work in a similar fashion. Our own street roller cam experience told us that a lower-number lobe centerline angle would help make a more radical camshaft produce more throttle response–and driveability–down low, off-idle and throughout the mid-rpm range. This is where engine builders get funny, as they spend so much time tweaking specs to arrive at their own happy performance combinations, so short of buying a complete and similar 383 from Sherman, there’s always a Comp cam ground to his specs.

We think that all of you–at least those of you who are stuck on making more horsepower and squeezing all the performance you can from your combinations–will benefit from this exercise. At minimum you will come to learn that a 383 equipped with the late-model, cast-iron center bolt heads from Racing Head Service can help such an engine to well over 500 hp with a four-barrel carb. There are, as you know, a great number of available combinations and engine packages that easily produce 360, 400, 425 and 450 hp and more, so the choices are many. The real concern is ensuring that the vehicle application can handle that much power, whatever it is. For those applications that can handle more, this kind of power can be achieved using the traditional bigger heads, more camshaft and larger carburetion. But the price will grow accordingly, as these “personalized” aftermarket engine packages can get expensive. For those who divide power levels into dollars, this combination is a bit different, and a lot more affordable.

DYNO RESULTS

Joe Sherman especially wanted us to expound upon the 10:1 pump-gas compression-ratio combination. This means you can drive the car/truck any time, anywhere and not need to resort to special super-high-octane gasoline or a race-fuel mixture. He also wanted to emphasize the cranking compression figure of 200 psi–the higher, the better. This is what makes an engine run strong, and it is a telltale sign that the pistons and rings and cylinder walls are getting along great. As the compression ratio goes up, the need for more advanced timing goes down. Sherman allowed that such an engine would run great at 35 degrees total advance. While some shops use dynos that are run with no mufflers, Sherman runs 1-3/4-inch primary pipe dyno headers with 3-inch Hooker turbo mufflers. The mufflers are the straight-through design, and better replicate what the engine will see once installed. Remember, too, that Sherman’s “own” Comp roller camshaft has a 106-degree lobe centerline angle, so it idles with authority at 900 rpm.

The dyno results were impressive: At only 4,000 rpm, the street engine produced a whopping 504 lb-ft of torque. With such a desirable torque curve peaking at 4,600 rpm with 523 lb-ft, it settled to 513 lb-ft at 5,000 rpm, and 504 at 5,200 rpm. Even at 6,200 rpm, the torque output was still an impressive 455 lb-ft! The horsepower began to come on the pipe at about 3,800 rpm, with 360. At 4,200 rpm, that number climbed impressively to 409 and reached 508 at a mere 5,400 rpm. At 6,000, 6,100 and 6,200 rpm, power is a mighty 536, 539 and 537, respectively. Consider such a potent street combination with a manual transmission or an automatic with a 2,800-rpm-stall-speed torque converter. What you will have is 467 lb-ft of torque stump-pulling you at only 3,000 rpm (at full throttle).

Noting the lesser overall weight of the small-block Chevrolet engine, this kind of power production per dollar is difficult to outdo. Depending on what particular Chevy you own, you can dress up the engine or make it look as factory as you wish and then go cruising. With an engine like this, don’t forget to make sure that your chassis and brakes are up to snuff; only then can you have a well-balanced “sleeper” 383 that puts out like the big blocks.

SHERMAN’S 383 PARTS CHOICE, AT A GLANCE

Now let’s take a look at Joe Sherman’s personal engine component choices, as well as what he specifically thought about each item, in his own words.

EDELBROCK RPM AIR GAP INTAKE MANIFOLD:

“This aluminum intake manifold has proven to be the best in the 3,000-6,000 rpm range. After years of comparison testing against non-air-gap manifolds, it appears this air gap feature is worth 5-7 hp on the right engine.”

BARRY GRANT SPEED DEMON CARBURETOR:

“This is a 750cfm, street-engineered four-barrel, not race engineered. It has correctly sized idle circuits for street-performance engines with camshafts in the area of 220-240 degrees at 0.050-inch cam specs. This carb’s phasing is extremely accurate.”

SRP 9.8-to-1 DISHED FORGED PISTONS:

“These SRP dished pistons are made by J&E Pistons as an off-the-shelf item. They are offered with either a dome, flat- or dish-top configuration, depending on your compression needs. J&E piston rings accompanied the pistons. Both come highly recommended.”

ARP HEAD & MAIN STUDS:

“To keep everything in place for years to come, ARP head and main cap studs were selected. Notice that the latest versions have a hex key in the top. An Allen wrench is used to allow for much easier installation and, if necessary, removal. This is very neat.”

MILODON OIL PAN:

“A Milodon oil pan was purposely selected for several reasons. First, it holds a few more quarts of oil. Second, it was made for stroker engines! Its pan rails feature rod clearance indents. Not only do the bottoms of cylinder walls have to be notched, but so does the oil pan. But not so with this trick Milodon oil pan. Yes, it also comes with a built-in windage tray.”

CRANE CAMS DISTRIBUTOR AND ELECTRONIC IGNITION COMP:

“It has a completely adjustable electronic advance curve. It can be easily recalibrated with a screwdriver without removing it from the engine. Both small- and large-cap models are available. Complete with ignition amplifier box, wiring and instructions, it does a very good job. It’s not cheap, but it’s worth it.”

RACING HEAD SERVICE CYLINDER HEADS:

“Formerly called Pro Topline heads, they were recently bought out by Comp Cams and are now marketed under its Racing Head Service logo. By description, one could define these heads as upgraded Chevy Vortec-style heads. Out of the box, they flow about 8 to 10 cfm better by comparison to the Chevy head, and they come machined for screw-in studs and guideplates. We spent some time on porting them, and this work picked up the intake port flow by an additional 10 cfm and the exhaust port flow by 30 cfm. This can be equated to an additional 20 to 30 hp over out-of-the-box GM Vortec heads. We milled the original 64cc heads to get the compression up to 10:1, and this required 0.030-inch milling off the head decks.”

COMPETITION CAMS BEEHIVE VALVE SPRINGS:

“These springs are the latest state-of-the-art valve springs from Comp Cams. In some situations, these springs and their much smaller titanium retainers have been shown to help make as much as 40-50 more horsepower!”

COMPETITION CAMS ROLLER ROCKER ARMS:

“This 383 engine has 1.60:1 ratio roller rocker arms on the intake valves and 1.52:1s on the exhaust valves. Tests reveal horsepower increases of about 15-18 hp here.”

COMPETITION CAMS CAMSHAFT:

“It is a brand-new XFI Extreme Energy hydraulic roller grind. It is close to race technology but has been adapted for street use. Its specifications are confidential at this time. [Try this on for size: 236/242 degrees at 0 .050 inch on a 106-degree lobe centerline.] A much larger flat-tappet cam could be used to make similar power, but continually starting and stopping over a period of time may cause lobe wear. Not so with a roller camshaft. Roller cam benefits include quieter operation with no required maintenance.”

SCAT CRANKSHAFT AND RODS:

“This 383 engine has a Scat 9000-series, special high-grade cast-iron crankshaft. All of its counterweights are radiused for less oil drag. Scat is the only manufacturer to use this better grade of metal in its crankshafts. The Scat rods are made from 4340 steel and are 6 inches long center to center (wrist pin center to rod journal center). They are I-beam type and have been designed to clear everything on a 383 or 400 Chevy stroker buildup. I find Scat has really done its homework.”