European Market Leader CTEK Enters the U.S. Market With Incredible Technology for the Misunderstood Battery Charger

If you are going to connect anything automatic to your car, especially when dealing with electricity, lead and acid, you owe it to yourself to do a bit more research rather than pulling just any super-discounted, off-the-shelf item and connecting it to something as potentially volatile as a lead-acid battery. But we have, haven’t we?

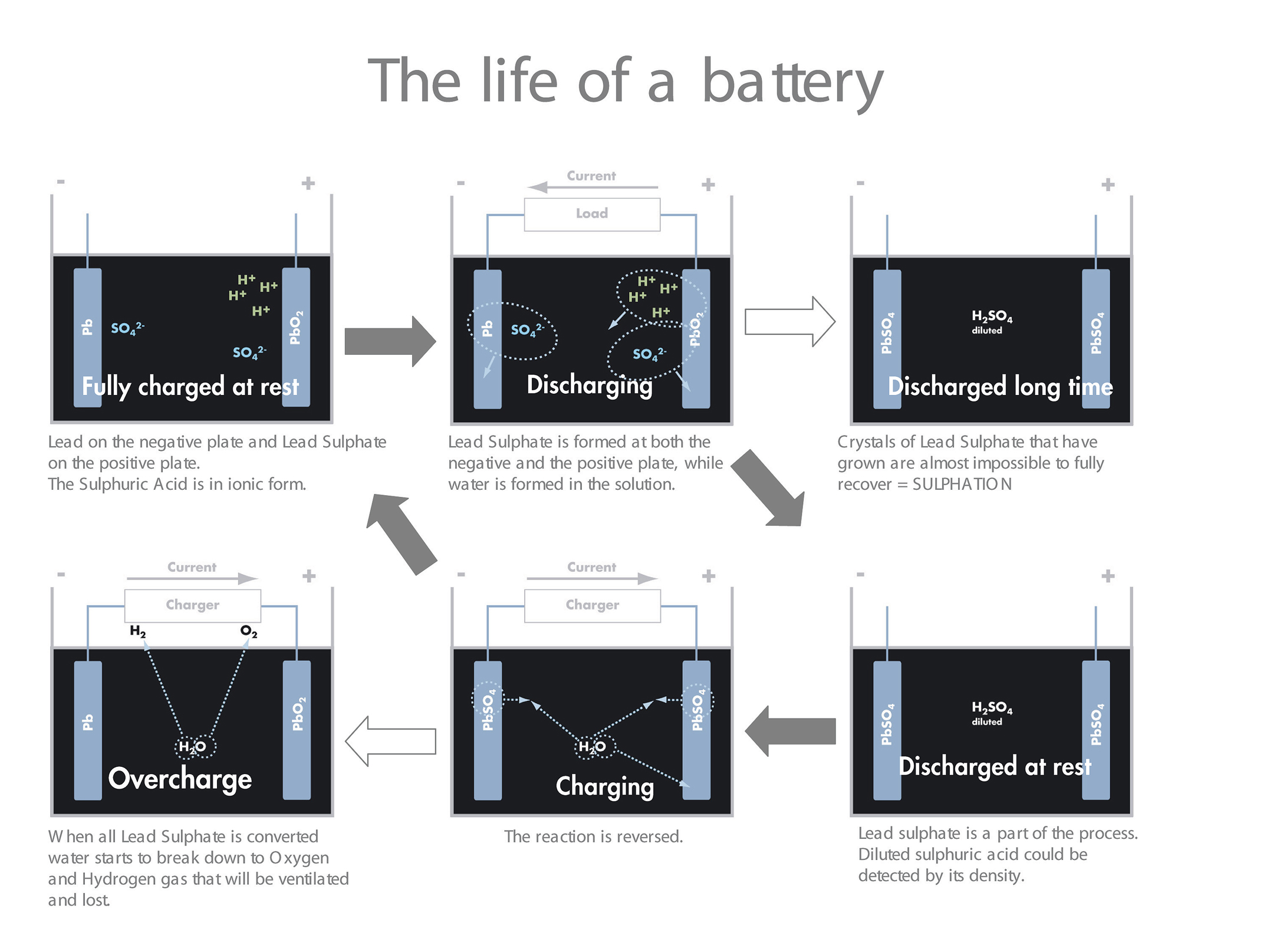

As you know, a battery is comprised of the most unsavory materials: acid and lead. You should avoid sulfuric acid and lead in any form at all times, which is why a spark-free, well-controlled voltage battery charger should be considered a vital accessory. Even then, it’s a good idea to wear protective goggles and gloves when coming in contact with batteries as an eruption or explosion of any kind would not be a pleasant experience. The simple precondition for such an explosion is that energy be present, often in the form of a spark. A spark of any kind in the correct environment may ignite the oxy-hydrogen gas that is frequently present in the battery. Even static electricity—something as simple as removing a label—is sufficient to generate voltage above 10,000 volts, or carrying a battery, casually rubbing it against certain types of clothing and then placing it on even a plastic pallet can discharge very high voltages. If and when gas is present, the risk of an explosion is great. Any number of contributing elements could cause a spark to set off this gas, so be particularly cautious around low levels of acid. This is why it is important that we better understand why a spark-free charger is a good idea in and around our garages.

up the vehicle to save onboard memory functions in case of battery failure.

Admittedly, when we saw the words, “the smartest battery chargers in the world,” we stopped to take notice. But this CTEK slogan intrigued us more than convinced us. We didn’t know what CTEK was, and we were not as knowledgeable as we perhaps should have been regarding battery chargers. But to be more cautious in our battery charger consideration and selection, we needed to know more. Here’s some of what we learned.

Europe-based CTEK Sweden AB recently established a U.S. headquarters in Cleveland to more effectively introduce its unique line of battery chargers here in America. For starters, we learned that there’s a certain seriousness about this company and its intent. Next, we learned that CTEK specializes in the design and development of what it calls the “smartest” battery charger, and that they are suited for all types of lead-acid batteries. Well, aren’t all battery chargers meant for all types of lead-acid batteries? How do you know otherwise when pulling one off the shelf at your local discount mass merchandiser? Maybe it’s not such a good idea..we needed to learn more.

CTEK was founded in 1997, and digging deeper we learned that it is a sister company to a highly skilled Swedish technology company, Creator, which was founded in 1982 by Bengt Wahlqvist, now the CEO of both companies. What we found even more interesting is that CTEK established such an exceptional reputation for its products that it became the European market leader in a very short time. Europeans are not noted for change and are not generally open to new developments outside of their own borders. Add to this associations formed with such prestigious auto companies as Porsche, Mercedes-Benz, Maybach, Aston Martin and even Harley-Davidson Sweden, and you’ll get the idea that although alliances such as these do not occur easily, there’s sound reasoning behind it when they do. So how can a company designing and manufacturing battery chargers make such a difference?

Sister company Creator is a standalone product development group with its own resources for industrial design and both mechanical and electronics development, including modeling and prototype work. In essence, they administer and execute product development for companies worldwide. Enter sister company CTEK. Not only does CTEK have its own internal development capabilities, but it also has total access to the incredible assets of Creator, which as you can imagine includes 3D imagery, incredible surface modeling software and an electronics lab that would keep Thomas Edison happy for another lifetime. It is, after all, the knowledge, experience, and all of the electronics equipment (ESD-protected electronics lab, fine-pitch circuit soldering capability, computer-based development for micro controllers and digital signal processors, all sorts of programming equipment, and CAD systems for drafting circuit designs, layout and circuit allotment, connectivity, and all of the necessary test equipment, including EMC equipment for measuring emission and immunity, which you will see referenced in the accompanying charts) that made it all possible. Couple this with CTEK’s programming for battery chargers, which through years of advanced research in battery electronics and electrochemistry, helped CTEK develop what they consider a line of battery chargers that not only has superior technology, but actually addresses consumer needs and safety. It’s pretty impressive, and I only thought I was charging my batteries!

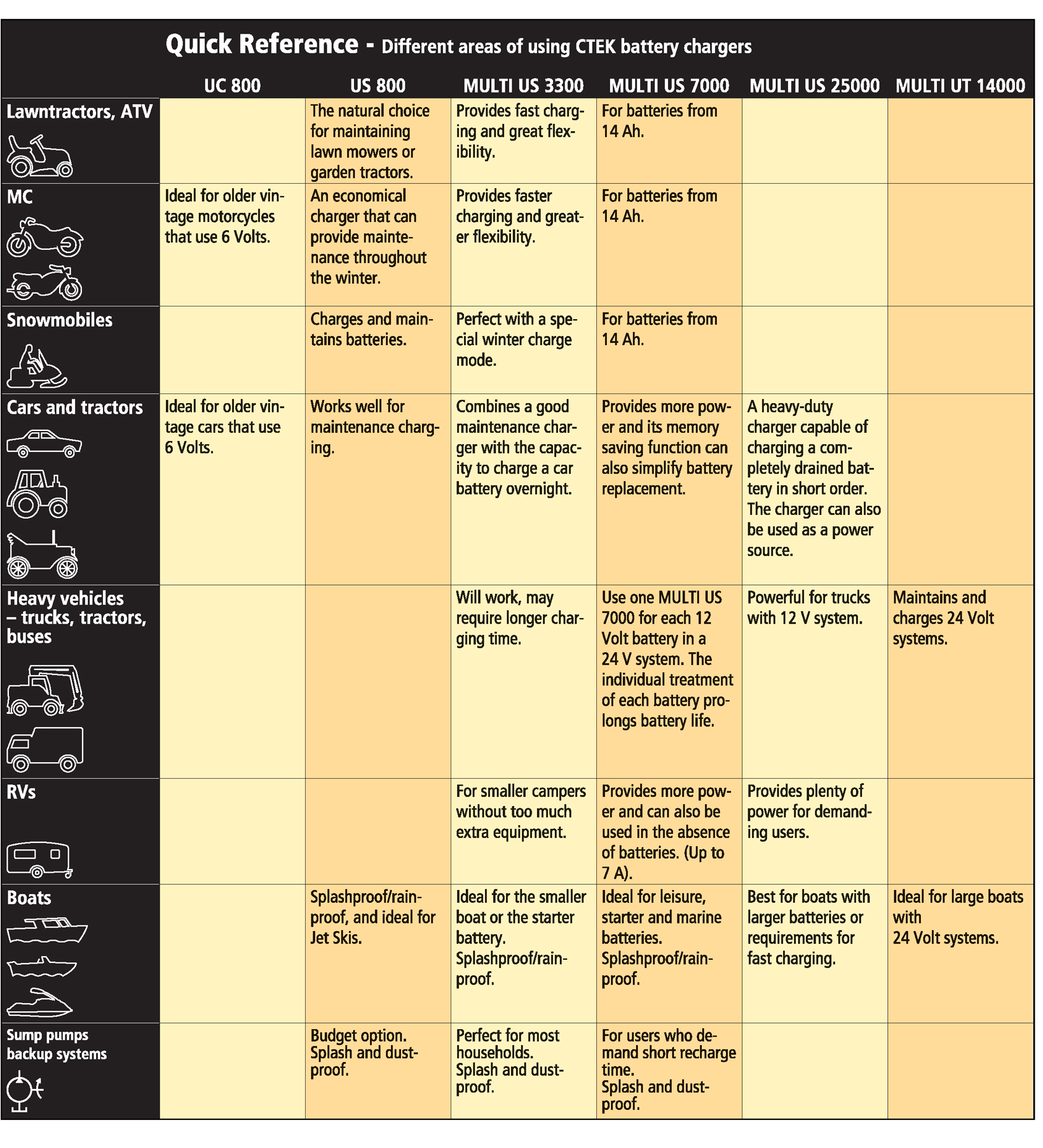

Designed for both consumers and professionals, the purpose of CTEK’s product is to prolong the life of 12- and 24-volt batteries. That’s a straightforward mission statement that makes logical sense considering their recent developments to create ideal battery chargers for all of our automotive needs. But because of the engineering that has gone into them, the use of these smart little chargers has much wider range, far beyond our cars and trucks or even the motorcycle or ATV in the garage. Personal watercraft, snowmobiles, campers, RVs, boats, lawn tractors and even standby power generators must be relied upon in case of a power outage. To handle all of this, CTEK has utilized switch-mode technology with foolproof cycle modes for optimum battery recovery and maintenance. And they’ve done this thanks to the sophisticated lab equipment available to them. The electronic switch-mode technology ensures maximum battery life and longer performance from your battery, and this patented protection guards against any sparks—short circuit or reverse polarity—to eliminate consumer fear or worry about charging a battery. The basic unit is a sleek, sealed design, and they are compact, lightweight and weatherproof, which means that these “smart” chargers are even approved for outdoor use. That alone spoke volumes about the product to me.

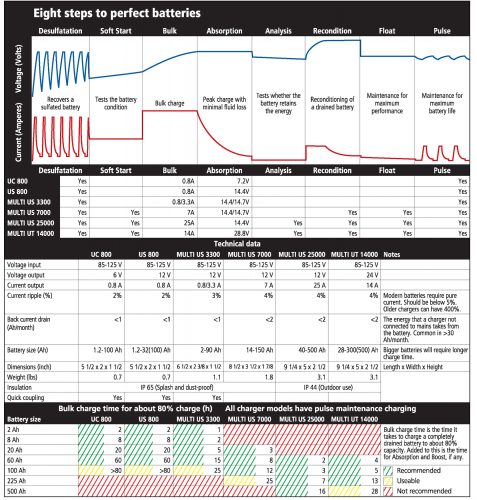

While it’s not up to us to tell you what the ideal battery charger is for your automotive and recreational use, let’s begin with CTEK’s Multi US 3300 battery charger, which just happens to be the best-selling charger in Europe today. The unit is not only designed for battery maintenance of any 12-volt lead-acid battery, but the 3300 also provides quick recharging, making it fast and flexible. Along with its switch-mode technology, a four-cycle intelligent process for perfect battery maintenance and charging, this unit is virtually foolproof to connect, regardless of where the battery is located. The four-cycle intelligent process involves four things: 1) desulfation, which wakes up a sulfated or undercharged battery; 2) bulk charge, which begins charging at 0.8/3.3 amps; 3) absorption, which applies peak charge at 14.4/14.7 volts until the battery is fully charged and 4) pulse, which sends out current pulses for charge maintenance.

The 3300 is small, compact and uniquely shaped compared to conventional chargers, and it’s light at 1.1 pounds, making it easy to carry or transport. The unit is fully sealed, making it dustproof, splash-proof and weatherproof. Because it is approved for outdoor use, there’s no need to remove the battery and carry it to an indoor location; simply connect the charger. It has a cold-weather boost mode, which enables faster recharging even in the coldest winter months, and it comes with quick-connect leads, which will allow you to permanently attach its connecting wires to the battery and snap-plug the charger in, which means quick and easy hookup, regardless of how difficult battery locations may be. And best of all, the 3300 is totally flexible; it works with virtually any lead-acid battery (see battery types sidebar), including flooded, maintenance-free, gel and AGM, and it is the recommended battery charger for the Optima RedTop battery.

There’s also a Multi US 7000 battery charger, which is a powerhouse of sorts in terms of battery chargers, as it is not only designed to recharge any lead-acid battery, but it can also be used as a power source which allows in-place recharging of batteries without losing vehicle power, so none of your vehicle’s memory cells go to waste (security codes, radio stations, clock, convenience settings and so on). The Multi US 7000 is also essentially foolproof to connect, without fear of weather, and its switch-mode technology includes a seven-cycle intel process. In addition to the desulfation mode of waking up an undercharged battery, its soft start tests the battery condition, the bulk charge begins charging at 7 amps, and the absorption mode applies peak charge at 14.4/14.7 volts until fully charged. The recondition mode is applied to the drained battery, and the float mode is a float charge that is applied for the maintenance of maximum battery performance. Finally, the pulse mode sends out current pulses for charge maintenance. That’s a lot for a small charger; heck, that’s a lot for any size charger.

At a light 1.8 pounds, the charger is fully sealed and approved for outdoor use. It, too, has a cold-weather boost mode and recondition capability, which reconditions deeply discharged batteries. The optional power supply is a float mode that provides 7 amps of power without a battery connected (to save those memory items) and has quick-connect leads for hard-to-reach battery locations. And, of course, the Multi US 7000 works on all lead-acid batteries, including flooded, maintenance-free, gel, AGM, starter and deep-cycle batteries, and it is the recommended charger for Optima YellowTop batteries.

Then there’s a less conventional, smaller charger, the US 800 battery charger, which is designed for smaller 12-volt lead-acid batteries (for motorcycles, snowmobiles, ATVs, watercraft and so on), making it an economical choice for battery maintenance. It can even be used in the storing of vintage vehicles or super rods that are not in regular use. The US 800 is also virtually foolproof, weighs only 1 pound, and its fully sealed design makes it weatherproof and approved for outdoor use. It comes with quick-connect option leads and battery terminal clamps, and it works with all lead-acid batteries, including flooded, maintenance-free, gel and AGM units.

As we are constantly working on our vehicles in an effort to upgrade and improve them, our learning experience here tells us that these are just the kinds of accessory items that not only come in handy when you need them, but will protect your investment when you don’t notice them. This level of quality in something we might otherwise take for granted serves as a useful preventative maintenance tool that helps eliminate the ongoing headaches of specialty car ownership. For more information on these hot new items, contact CTEK at 330/963-0981, or visit www.ctek.com. And as they say, an ounce of prevention is worth a pound of cure.

DIFFERENT

BATTERY TYPES

We may not all be familiar with the numerous standard abbreviations of lead-acid batteries, and if you fit into that group, here’s an explanation of what the following terms mean: flooded (wet), maintenance-free (MF), calcium/calcium, VRLA, gel, AGM and hybrid. The flooded (or wet) battery continues to dominate the marketplace and remains the most common type of battery today. It consists of freely suspended plates that are insulated from each other (usually with the negative plate sealed in a small polythene separator bag). The fact that these batteries can be manufactured inexpensively is no doubt why this design remains so prominent, as even an inexpensive, normal car battery contains around 130 components. Over the years, production methods have been refined, the materials used are relatively basic, and the result is a low-price battery that offers satisfactory service to the general motoring public.

The flooded (or wet) battery continues to dominate the marketplace and remains the most common type of battery today. It consists of freely suspended plates that are insulated from each other (usually with the negative plate sealed in a small polythene separator bag). The fact that these batteries can be manufactured inexpensively is no doubt why this design remains so prominent, as even an inexpensive, normal car battery contains around 130 components. Over the years, production methods have been refined, the materials used are relatively basic, and the result is a low-price battery that offers satisfactory service to the general motoring public.

An improvement on the older-style batteries with removable filling caps is the maintenance-free battery (MF), which in its standard form is a wet battery in which the design keeps gassing to a minimum, and it includes a sealed battery box to keep the gasses inside. An ample amount of acid means that the fluid can last throughout the entire service life of the battery without needing to be topped off. This design is not new, however, as development has been around for more than 20 years. Advancements have been made over time from the high-antimony battery (which dominated the market), where the basic element antimony was added to the grid as more of a manufacturing consideration than anything else. Refining production methods witnessed the introduction of hybrid batteries, with the antimony on the negative plate being replaced by a calcium alloy, which substantially reduced gassing and therefore water consumption.

The next phase of development is called calcium/calcium, which involves the antimony on both the negative and positive plates being replaced by calcium alloy. The benefits are obvious; fluid loss within the battery is about 80 percent lower than that of an antimony battery, which also means that the self-discharge is lower. By design, these batteries can remain unused for longer periods of time without losing serious charge. The disadvantage is that they are far more demanding when charging, especially if they have been overly discharged. You’ve probably experienced this and have discarded perfectly good batteries because you were unable to deep-charge this type of battery with a conventional battery charger.

Efforts made in avoiding the gassing in batteries had a positive effect, namely that the bubbles moved about in the acid, causing it to be thoroughly mixed when charging. Without these bubbles, the acid can stratify at different densities (acid weights), which is quite a common phenomenon. When you are looking for an even weight of 1.28, an acid weight of 1.35 or more at the bottom and about 1.17 at the top may cause the battery to be affected by sulfating. This can and will increase grid corrosion, despite the battery being fully charged.

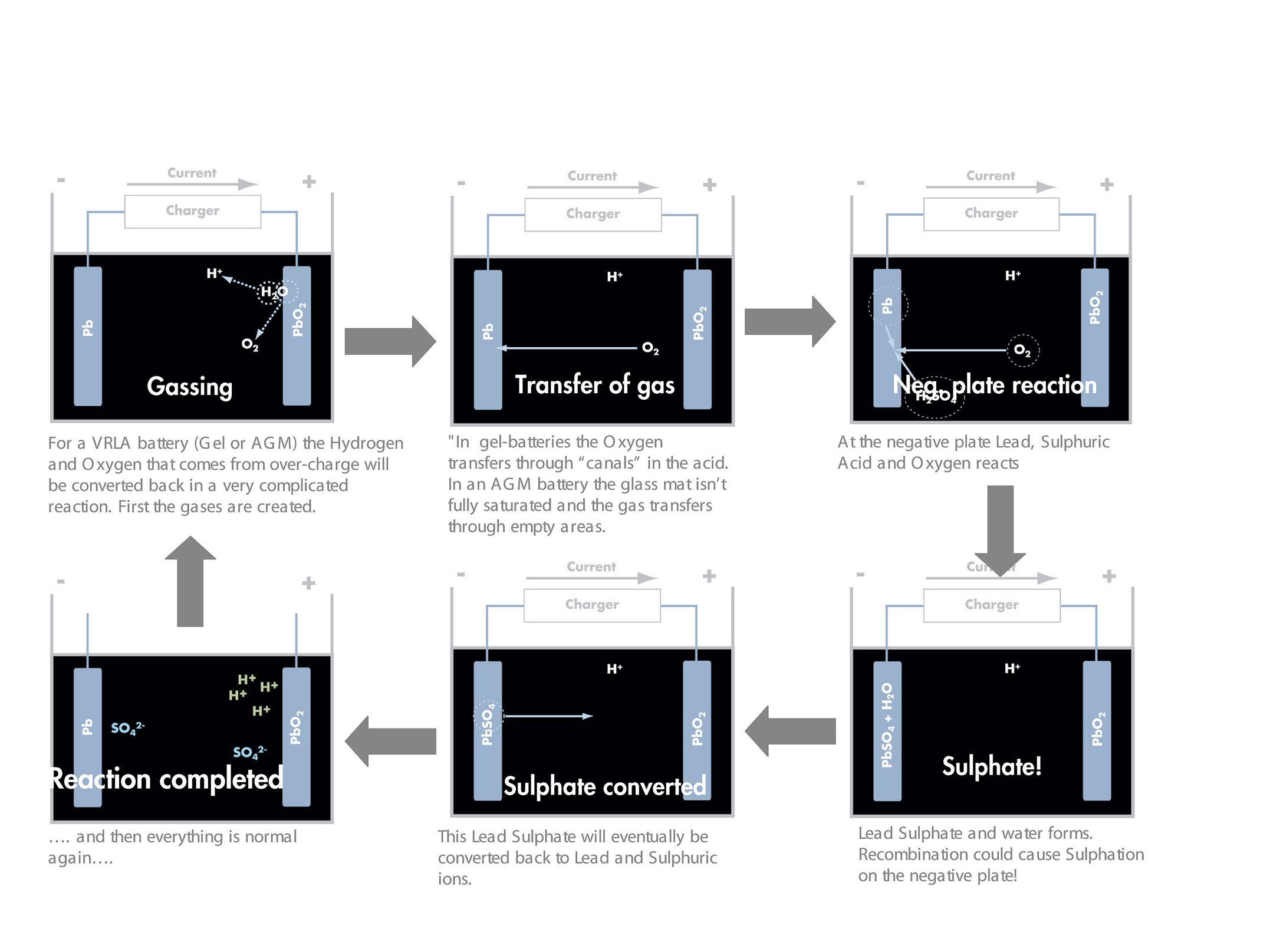

An entirely different way of controlling fluid loss goes under the generic name of VRLA (Valve Regulated Lead Acid). In this case, the battery box is designed as a small pressure vessel with safety valves. If you confine the oxygen and hydrogen gasses, they can react with each other and turn into water. This is called recombination and is a brilliant way of all but eliminating fluid loss. It is not possible to confine and recombine all of the gas, but the loss is reduced significantly.

VRLA is available in two main battery designs, gel or AGM, each of which is constructed in totally different ways. A gel battery has some elements, usually silicon compounds, added to the acid to ensure that it gelatinizes and thereby guarantees that no flooded acid can leak. The oxygen gas drills channels in the gel from the positive to the negative plate, where it meets the hydrogen gas and recombines into water. They have excellent capacity, but the somewhat higher resistance in the acid means that they can have limitations as starter batteries. They can withstand over-discharging very well; i.e., when the battery is drained down to a 20-percent state of charge. Gel batteries are very robust and are often used in floor-cleaning machines and golf carts. When gel batteries are mentioned in a motorcycle context, it is often a misconception and is more likely to be an AGM battery.

CHOOSING

THE CORRECT

CHARGER SIZE

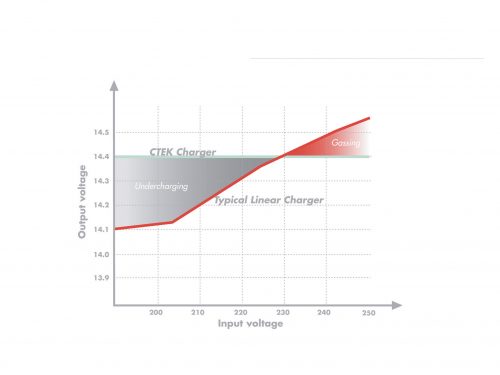

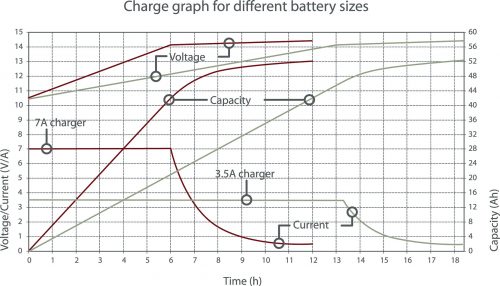

CTEK says that average is best. As in life, too much or too little of anything may not be best, and when it comes to battery chargers, you have two elements pulling in different directions. For example, a wet battery can withstand a lot of punishment, and you always have the option of topping it off with water. On the other hand, a pure lead AGM battery can withstand extremely high loading current. Modern chargers with more control and cleaner, direct current also widen the permitted field of application. An old rule of thumb claims that the recommended size of the charger can be worked out by multiplying the capacity of the battery by 0.1 to give the recommended current in amperes. However, with a more modern CTEK charger, you can charge with a much more powerful model, as the current is clean and the voltage is well-controlled. Charging with a current that is four times greater than the old recommendation is normally no problem with a CTEK charger.

A charger that is too small will take far too long to charge, so much so that it sometimes becomes impractical. A small appliance, such as a floor cleaning machine or wheelchair, has perhaps eight hours before you can use the equipment again, at which time the user expects a battery at its full capacity. For a small battery, the time that the battery is at full voltage is far shorter than for a large one, so refer to the charge graph to better understand that the small charger has 13.5 hours to reach full voltage and will have achieved almost 90 percent charge. From here to full charge, however, takes only five hours. The large battery is up at full voltage after six hours but is only at 80 percent of its capacity and requires six additional hours to reach full charge. You can also look at this as if you simply discharged 10 percent from the battery; the small charger is then just as quick as a charger twice its size as it is the battery that dictates the current flow.

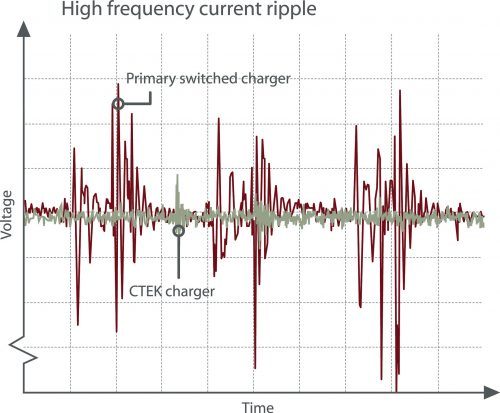

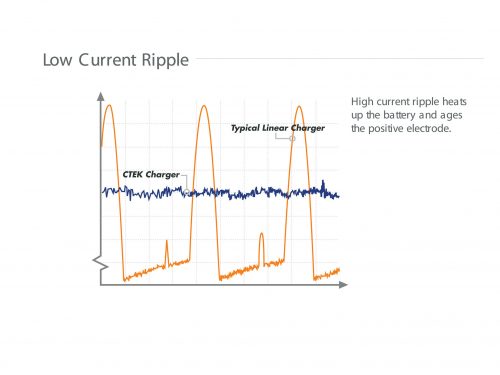

A charger that is too large is unnecessary for two reasons. First, the heating of the battery is greater, which is unfortunate. The ripple in the charger also has an effect here, i.e., how unclean the current is. A charger with high ripple, which is common in most linear chargers, heats the battery more, which means that the current must be kept down. A modern switch-mode charger has a ripple so low that the charger can be used for batteries that are smaller than you might expect. A good example of this is the CTEK MULTI US 3300 with 0.8-amp charge current, which has been used for a 2-amp battery with only 2 degrees of temperature rise. A normal maximum temperature rise is considered to be 3 degrees, which means that this CTEK charger covers an extremely wide range. It is possible, of course, to estimate the amount of high current ripple that contributes to heating the battery. A simple rule of thumb is that a traditional linear charger with 400 percent current ripple gives around four times as much heat to the battery compared to a modern charger, like the CTEK, that incorporates switch-mode technology. SR

By

By