Vortech Supercharged Cobra Killer

Original Story Release – May, 05

While it can be argued that the new three-valve engine is merely an evolution of the older 4.6-liter two-valve, the changes to the new engine represented huge steps in the right direction.

Although the new mod motor shares the basic short block, the top end is all new. As is evident by the new three-valve designation, the major design change on the ʼ05 mod motor is the headgear. The much-needed airflow improvements come courtesy of an additional intake valve combined with redesigned intake and exhaust ports. The airflow improvements were carried over to the intake manifold, as the three-valve engine has been blessed with a new composite intake manifold that offers slightly shorter runners, improved (radiused) port entries and a repositioned throttle body. The new throttle body also features electronic drive-by-wire actuation. Additional electronic trickery includes variable cam timing by which the cams are advanced and retarded to optimize the power curve at high and low rpm. Traditionally, advancing the cam improves low-speed torque production, while retarding the cam events improves top-end horsepower. Using the new variable cam timing, the three-valve engine offers the best of both worlds.

As good as the new three-valve engine is in stock trim, we were here to see how much we could improve it with the installation of a new Vortech supercharger. The first step was to run the engine in stock trim, or at least in near-stock trim. The ʼ03 GT engine was supplied by our friends at Vortech, without whose help this test would never have happened.

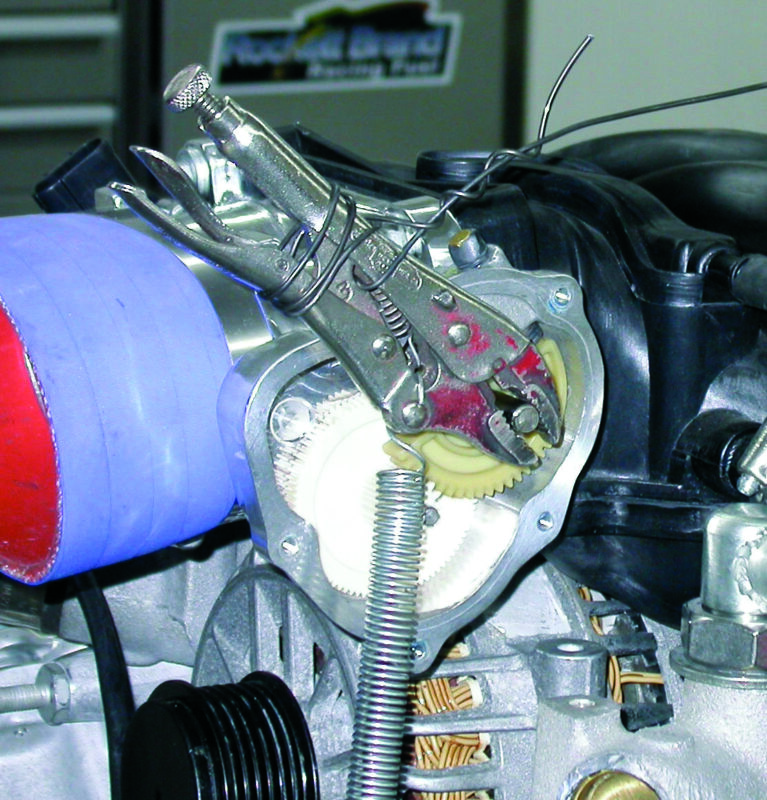

A few changes were necessary before running the new three-valve GT engine on the engine dyno. First, the drive-by-wire had to be replaced with a mechanical throttle system. Next, we installed a Meziere electric water pump to replace running all the accessories. We then replaced the factory coil-on-plug ignition system with a coil pack from a ʼ98 two-valve GT engine. The change in ignition had no effect on performance other than allowing us to utilize the FAST management system. We then installed a set of JBA long-tube headers in place of the stock cast-iron exhaust manifolds. The JBA long-tubes were worth as much as 18 lb-ft all by themselves, but we wanted to ensure that the ʼ05 three-valve engine had plenty of exhaust flow once we installed the Vortech.

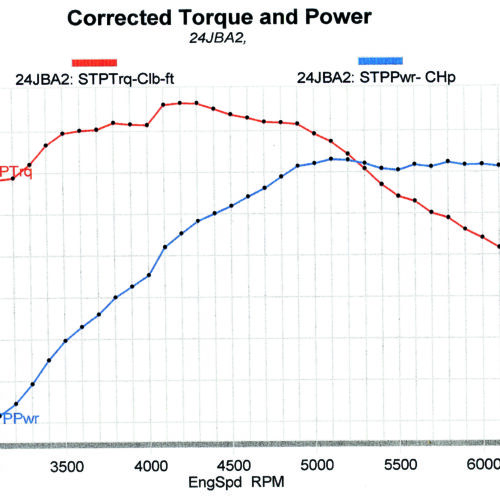

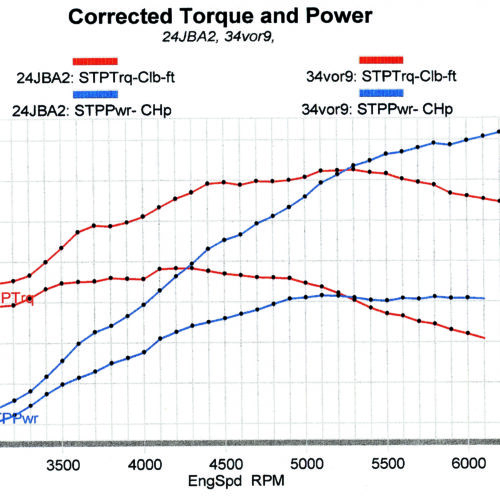

Breathing through the stock throttle body and exhaling through the JBA headers, the ʼ05 4.6-liter three-valve GT engine pumped out 356 hp at 5,800 rpm and 392 lb-ft of torque at 4,300 rpm. The torquey mod motor exceeded 350 lb-ft from 3,300 rpm all the way to 5,300 rpm.

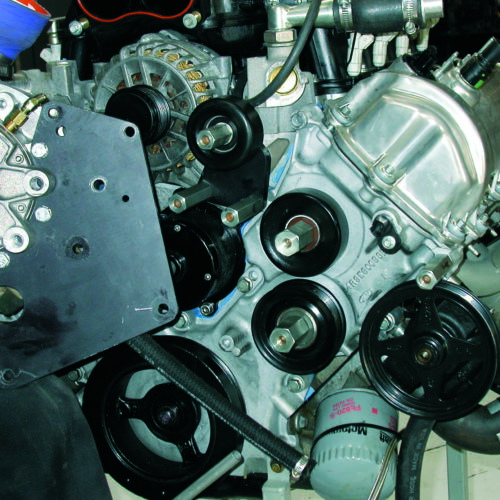

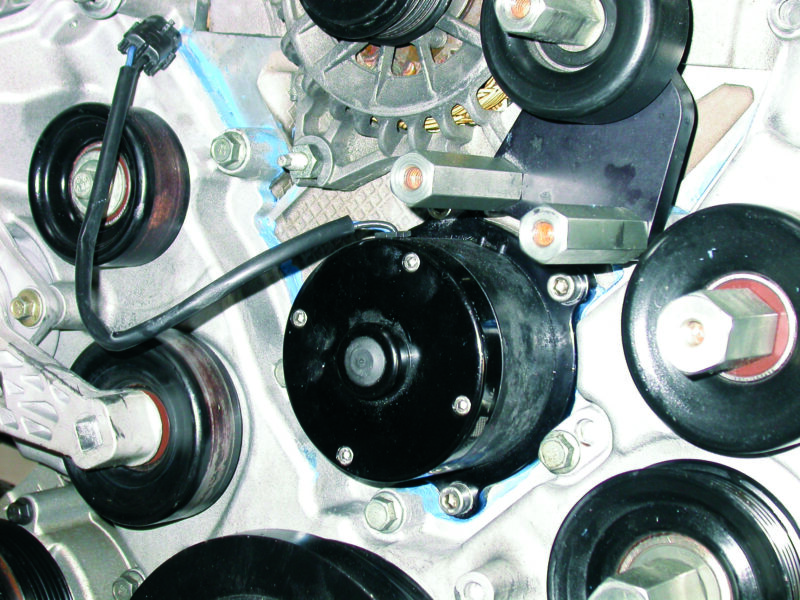

After running the three-valve engine in normally aspirated trim, it was time to install the Vortech S-trim supercharger kit. Installation of the Vortech required replacing the electric water pump with the stock (belt-driven) unit. It was necessary to utilize all of the factory accessories to successfully drive the supercharger using the supplied drive belt. Like previous systems, the remainder of the factory accessories shared the six-rib serpentine drive belt used for the blower, greatly improving packaging. The Vortech S-trim supercharger was mounted to the driverʼs-side front cover using a dedicated mounting plate and a series of stand-offs. Also included in the Vortech kit was a short discharge tube. This standard kit did not include one of the Vortech air-to-water aftercoolers, although we will be testing that system in the near future. Of course, the lack of intercooling did not stop us from upping the boost pressure with a pulley change (read on). The Vortech kit was supplied with a 3.60-inch blower pulley, and when combined with the factory 6.5-inch crank pulley, it produced a drive ratio of 1.805:1. The drive ratio combined with the internal step ratio in the blower determined the impeller speed (and attending boost level) at the various engine speeds.

Having had nothing but success with Vortech products in the past, we had high hopes for the new ʼ05 three-valve GT kit. When applied to the new three-valve mod motor, the S-trim once again proved why there is nothing like forced induction when it comes to adding power. Did the Vortech add power? How does an extra 200 hp sound? Equipped with the Vortech S-trim, the 4.6-liter three-valve pumped out 559 hp at 6,200 rpm at a maximum boost pressure of 11 psi. As expected of the blown motor, the torque production skyrocketed as well, up from 392 lb-ft at 4,300 rpm to 513 lb-ft at 5,300 rpm. Given that the airflow and boost pressure increase with engine speed, the power gains followed suit. The blower added 30 lb-ft at 3,000 rpm but upped the power ante by an amazing 200 hp at 6,000 rpm. With the addition of the JBA headers and Vortech supercharger, the three-valve GT was now pumping out supercharged four-valve Cobra power. Actually, scratch that last comment, as the supercharged GT was now making “modified” ʼ03 four-valve Cobra power. The new three-valve configuration seems to take to supercharging every bit as well as the four-valve engines—a compliment indeed.

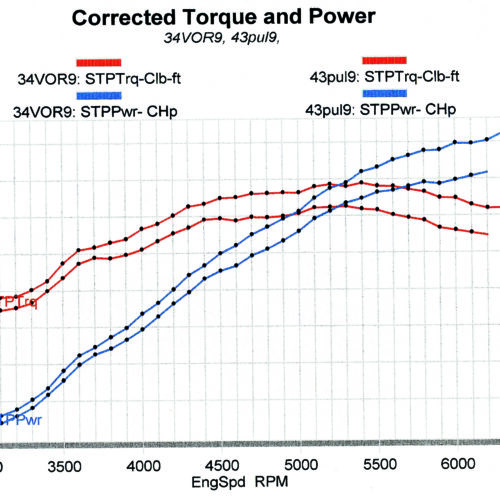

The jump in boost pressure upped the power output from 559 hp to a whopping 613 hp. The peak torque was up as well, from 513 lb-ft to 545 lb-ft.

Naturally, we were elated with the power gains offered by the Vortech supercharger, but it must be said that the additional airflow supplied by the blower would be useless without proper tuning. We relied on the FAST management system to tailor the air/fuel to a pump-gas-safe 11.75:1. We also retarded the total timing from 30 degrees (in normally aspirated trim) to 22 degrees. Look for Vortech to supply the necessary tuning components to produce similar results on the street. It was this absolute control over the fuel and timing that allowed us to safely take the next step in performance. With a tad more fuel available from our 36-lb injectors, we decided to replace the 3.60-inch blower pulley with a smaller 3.33-inch version. The increase in blower speed increased the boost pressure by a maximum of 2 psi (from 11 psi to 13 psi) and power right along with it. As a hedge against damaging someone elseʼs engine, we spiked the pump gas with 2 gallons of 100-octane before letting the hammer fly with the smaller pulley. The jump in boost pressure upped the power output from 559 hp to a whopping 613 hp. The peak torque was up as well, from 513 lb-ft to 545 lb-ft. At this point we figured it was time to call it quits. Sure, it was no Halle Berry, but we succeeded in officially transforming the 4.6-liter three-valve GT into one serious Cobra killer.