Nothing Improves Power Output Like a Pressurized Breath of Fresh Air,—as This 775HP Stock-Block Stroker Proves

Here is an important safety tip. When you go looking to make huge power from your 5.0-liter Ford, the limiting factor will always be the weakest link in the chain. In the case of our supercharged 331 stroker buildup, the weakest link turned out to be the production block. Like most enthusiasts, we had no budget for a DART racing block or even a Ford Racing Sportsman block, but we decided to tempt fate nonetheless and go for a big power number on the dyno. Considering that the stock fuel-injected 5.0-liter was rated at a measly 225 hp, even a 300hp buildup would offer a welcome change in performance. Obviously, we were looking for something more than a welcome change. If 300 hp wasn’t sufficient, how about 400 hp, 500 hp or even 600 hp? True enough, 400 hp would make for spirited performance and 500 hp would allow your 5.0-liter to run heads up with a V-10 Viper, but 600 hp would place your Mustang squarely in supercar territory.

While a nice territory to visit, we wanted just a tad more from our buildup, so we set our sights on exceeding 700 hp. We knew that that stock block would not withstand that power level for very long, and that it would likely require detuning for daily street use, but we couldn’t help but tempt fate when offered a blower capable of 1,000 hp.

In terms of specific output, an engine that makes 1 hp per cubic inch is considered pretty healthy. A 300hp 302 makes for a snappy street performer, but think about an engine that effectively doubles that number. Producing 2 hp per cubic inch is certainly possible in normally aspirated trim, but the result will be far from streetable. Exceeding 2 hp per cubic inch becomes more and more difficult unless you opt for a little horsepower helper—in this case in the form of forced induction. Nothing improves the power output of an engine like a pressurized breath of fresh air. Boost supplied by a supercharger (or turbo) will dramatically improve the breathing of any engine. It makes no difference whether the engine is bone stock or heavily modified—all engines will respond to forced induction. In normally aspirated form, an engine actually has 14.7 psi of (atmospheric) pressure forcing air into the vacuum created by the downward-moving piston(s). Increasing the pressure in the manifold above atmospheric will result in improved cylinder filling. More air in equals more air out. In the case of turbos, doubling the (atmospheric) pressure (running 14.7 psi of boost) can double the power output.

Superchargers differ from turbos in that (in most cases) they are slightly less effective at supplying air to the engine. Add to this inefficiency the amount of power required to actually spin the crank-driven blower and you begin to understand why a turbo motor will almost always make more power than a supercharged engine at a given boost level.

Despite the parasitic losses associated with driving the supercharger, the centrifugal supercharger is capable of adding an impressive amount of power. In the case of our Novi 2000 supercharger, the power potential hovered around 1,000 hp, a level we could never hope to approach with our stock-block Ford, but it sure had a nice ring to it. When it comes to making big power from a supercharged combination, the best method is to start out with a good normally aspirated engine. In this case good meant not only that the internals (if not the block) were sufficiently stout to withstand the additional cylinder pressure, but also that the combination was sufficiently powerful in its own right, before resorting to the boost supplied by the blower. We mentioned that the power offered by forced induction is basically a function of the boost pressure relative to atmospheric pressure. If we double the boost, we can come close to doubling the normally aspirated power output. This convenient formula also means that the more powerful the normally aspirated combination, the easier it is to reach a given power level and the less boost pressure required to do so. If we have a 300hp engine and double the boost, we theoretically get 600 hp, while doubling the boost to a 400hp normally aspirated engine will yield 800 hp. Likewise, 10 psi to a 300hp engine can yield 504 hp (10 psi is 68 percent of 14.7, so we multiply 1.68 x 300 hp), and 10 psi to a 400hp engine can yield 672 hp.

The multiplier effect produced by boost pressure results in a dramatic difference in power. Therefore, building a powerful normally aspirated engine will allow you to reach a given power level at a lower boost pressure. It is obviously beneficial to run lower boost pressure as the inlet charge temperature is reduced, something that will decrease the chance of detonation. This is especially critical on the street, as an engine producing 500 hp on 7 psi of boost may actually be less likely to experience detonation than an engine producing 450 hp on 10 psi of boost. Although it seems contrary to common sense, the lower the boost pressure (for a given blower speed), the higher the flow rate of the blower. What this means is that a centrifugal supercharger spinning at 40,000 rpm will supply more air to the engine with just 7 psi showing on the boost gauge than at 10 psi.

The trick to this equation is: to lower the boost pressure at any given blower speed requires increasing the efficiency (or flow rate) of the engine. If we ran the Novi 2000 at 50,000 rpm on a stock 5.0-liter, it would likely produce a minimum of 18 psi, but doing so on a modified stroker motor like ours will result in not only a drop in boost pressure but also a dramatic increase in power. Talk about having your cake and eating it, too—less boost equals more power!

In an effort to maximize the power output of the normally aspirated engine, we decided to take the easy route by upping the displacement. When it comes to internal-combustion engines, it is always easier to make more power with a larger engine. If 400 hp is your goal, it will be easier to reach it with a 331ci engine than with a 302. It was with that line of thinking that we decided on a stroker motor. While we have made impressive power from a standard 5.0-liter 302, the lure of additional cubic inches was just more than we could bear. Our 331 stroker kit was supplied by Coast High Performance in the form of its Street Fighter assembly. The Street Fighter stroker kit included the 3.25-inch stroker crank (a stock 5.0-liter crank checks in at 3.00 inches), a set of 5.40-inch forged connecting rods and a set of Probe Racing forged pistons. The kit also included the necessary rod and main bearings as well as the piston rings for our low-compression pistons. Given that this was to be a dedicated supercharged street motor, we elected to run a slightly lower-than-stock compression ratio. Each Probe piston featured a 14.2cc dish to drop the static compression down to blower- and pump-gas-friendly 8.6:1 (with the 66cc chambers on our TFS heads). The dish volume included the dual valve reliefs designed to accept the standard inline valve heads as well as the TFS Twisted Wedge valve orientation. The CHP stroker also featured a billet main girdle to add some strength to the reciprocating assembly. We would be putting the strength to the ultimate test once we added the Novi 2000.

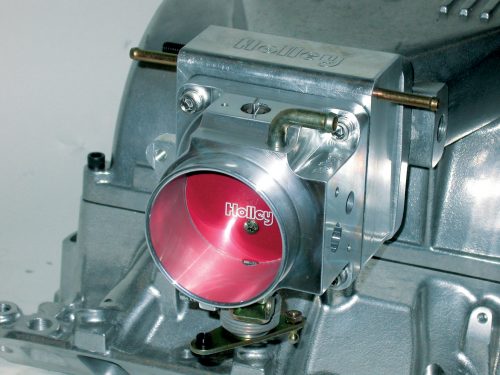

The CHP Street Fighter stroker assembly was stuffed with an Xtreme Energy XE274HR hydraulic roller cam. The dual-pattern cam offered a 224/232 duration (at 0.050-inch) split, a 0.555-/0.565-inch lift, split all on a blower-friendly 112 lobe separation angle. The CHP short block was also augmented with a Milodon road race oil pan and windage tray. The oil control offered by the Milodon pan offered some extra power by reducing windage as well as keeping the oil in place during those high-G cornering maneuvers. We used a Melling high-volume oil pump and heavy-duty driveshaft, along with 7/16-inch ARP head studs and Fel-Pro 1011-2 head gaskets. The awaiting short block was topped off with a set of TFS Twisted Wedge heads. Excellent performers right out of the box, we shipped ours to the flow experts at Total Engine Airflow, which increased the flow rate up to 294 cfm at 0.600-inch lift. As we said, more power normally aspirated equals more power under boost. The TFS heads were not the only things given the porting treatment, as the Holley SysteMax intake was taken to Extrude Hone for not only improved flow but much improved runner-to-runner flow balance. When Extrude Hone was finished with the Holley upper and lower intake, the SysteMax actually out-flowed the TFS heads. The Holley intake was finished off with a matching Holley 75mm throttle body.

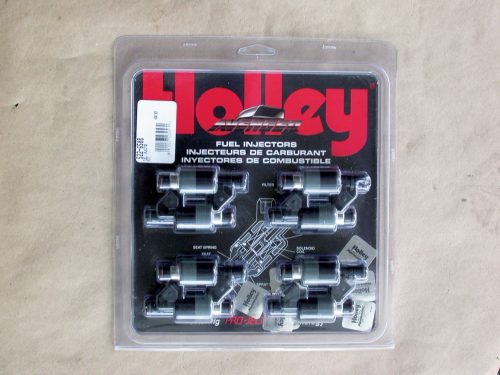

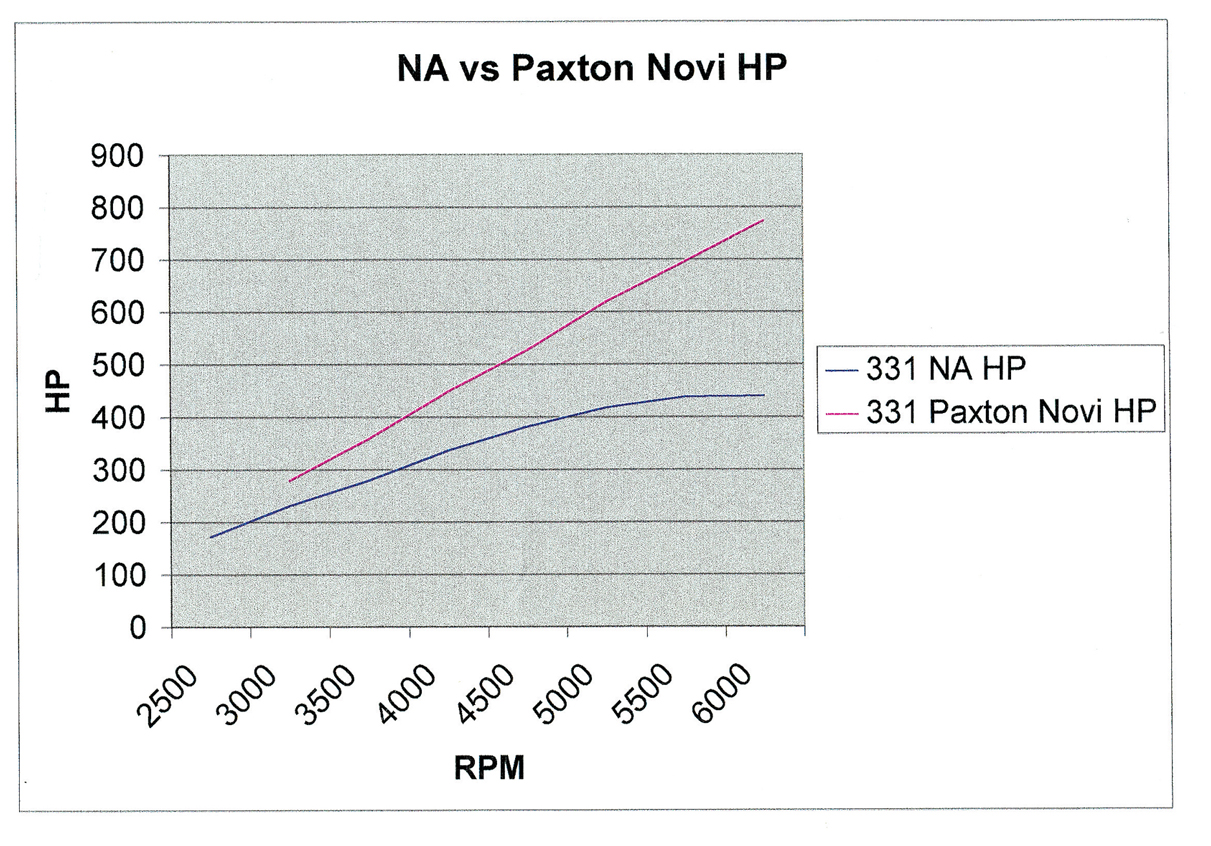

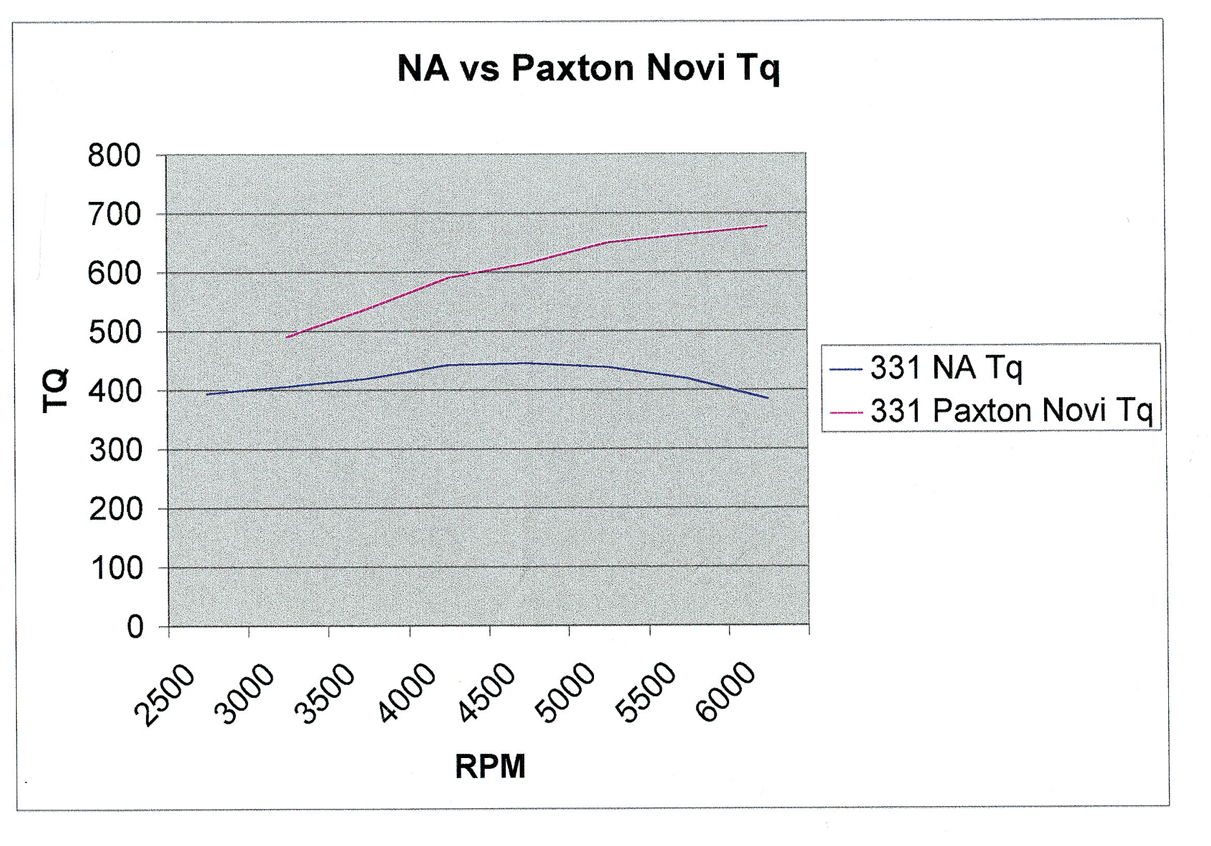

Exceeding 700 hp takes considerable fuel flow, so we used a set of Holley 50-lb injectors. The injectors were run with a Vortech billet aluminum fuel rail, an Aeromotive A1000 fuel pump and a Kenne Bell Boost-A-Pump. The ignition chores were handled by MSD, which supplied a billet TFI (EFI 5.0-liter) distributor, a set of wires and a blaster coil. With all the air getting in, a set of 1-1/2-inch Hooker headers was run to get it all out. A FAST management system was employed on the engine dyno, but Super Chips tuning software will be used once the engine goes into the car. To establish a normally aspirated baseline, we ran the 331 stroker before installing the blower. After tuning the FAST fuel injection to provide a 13.0:1 air/fuel ratio and 34 degrees of total timing, the 331 produced 441 hp at 6,000 rpm and 447 lb-ft at 4,500 rpm. The stroker produced an exceptionally broad power band, offering over 400 lb-ft from below 3,000 rpm to 5,750 rpm. Some of the credit for the exceptional torque curve can be given to the long-runner Holley SysteMax intake. Long runners help promote torque production. Get the runner length and cross section right and you have the makings of an exceptional intake. We were quite pleased with the power production of the stroker, and we were now looking forward to installing the Novi 2000 supercharger.

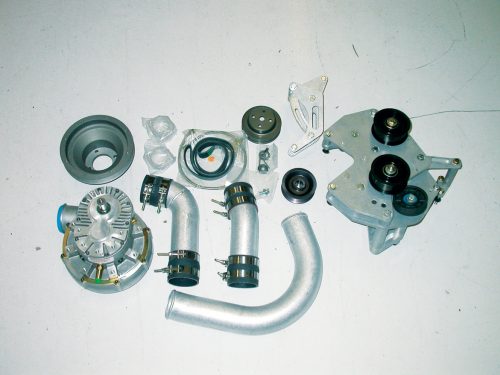

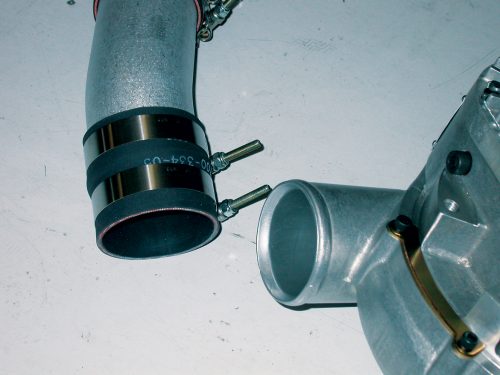

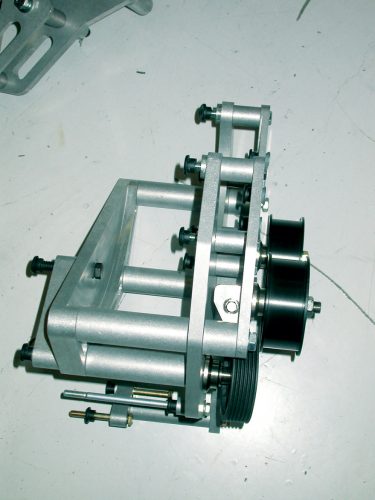

We used a Paxton 5.0-liter Renegade kit for our test. The highlight of this kit was the Novi 2000 supercharger. The most impressive aspect of the Novi 2000 supercharger was not just that it was capable of supporting 1,000 hp, but that it was equally at home running just 8 psi on your stock 5.0-liter. The unique impeller design has blessed the Novi 2000 with both impressive boost response (for a centrifugal) and peak power potential. Unlike most 5.0-liter applications, the Paxton Renegade kit mounts the blower on the driver’s side.

One of the critical elements in the success of any supercharged engine is the strength of the mounting bracket. Deflection in the blower mounting bracket can wreak havoc on the blower belt. A flimsy mounting bracket will allow the blower belt to literally walk off the end of the pulley(s). The Paxton mounting bracket assembly for the Renegade kit did exactly what it was designed to do, and features extra-beefy mounting plates and steel support columns. We never experienced a single belt problem during all of our testing, a rarity for a blower test.

living on borrowed time.

Equipped with the 7-inch crank pulley and a 3.5-inch blower pulley, the 331 stroker thumped out an amazing 776 hp at 6,000 rpm and 679 lb-ft of torque at the same engine speed. The engine was run on race fuel with 20 degrees of timing and with a safe air/fuel ratio of 11.7:1. The maximum boost pressure supplied by the Novi 2000 was 13.1 psi. Obviously, we will have to detune this combination for street use, as the stock block is certainly living on borrowed time. For now we will bask in the afterglow of our 776hp stock block.

The first thing to notice about the 331 stroker was that despite the low compression ratio (for street use with the blower), the 331 stroker produced impressive power in normally aspirated form. The 331 pumped out 441 hp and 447 lb-ft of torque. The additional cubic inches offered by the CHP stroker allowed the engine to produce the impressive peak power number at just 6,000 rpm. In fact, the CHP stroker exceeded 400 hp for more than 1,000 rpm (4,750 rpm to 6,000 rpm). As expected, adding the Paxton Novi 2000 supercharger (in Renegade kit form) resulted in a serious chink of power—likely more than our production 5.0-liter block will withstand for very long. Running a maximum of 13.1 psi, the Novi 2000 added no less than 335 hp. Since this Paxton Novi 2000 is capable of supporting 1,000 hp, it was just getting started at the 776hp mark. Note that the power curve was still rising rapidly at the self-imposed shut-off point of 6,000 rpm. We were definitely living on borrowed time running this much power through the production block, but the combination was certainly impressive.

The torque curve offered by the normally aspirated version of this stroker motor is a perfect example of why we go to the trouble of adding displacement in the first place. Not only did this (low-compression) 331 stroker produce 447 lb-ft of torque, but torque production exceeded 400 lb-ft from below 3,000 rpm all the way to 5,750 rpm. Part of the credit for the broad torque curve belongs to the impressive (Extrude-Hone ported) Holley SysteMax intake, but don’t forget the CNC-ported (by Total Engine Airflow) TFS Twisted Wedge heads and Xtreme Energy XE274HR cam. The torque curve produced by the Paxton supercharger is a function of the rising boost curve. On our Novi supercharged 331 application, the horsepower and torque peaks occurred at 6,000 rpm. Had we elected to rev the engine beyond 6,000 rpm, we would have likely reached the torque peak within the next 500 rpm. Unfortunately, our stock block limited the maximum revs to just 6,000 rpm.

Article Sources

FAST (Fuel Air Spark Technology)

901/260-3278

3406 Democrat Rd. Memphis, TN 38118

Holley Performance Products

270/781-9741

1801 Russellville Rd. Bowling Green, KY 42102

Hooker Headers, a Division of Holley

270/781-9741

1801 Russellville Rd. Bowling Green, KY 42102