Inside Dart’s CNC-Ported Honda Head

What can we say about VTEC Honda motors that hasn’t already been said thousands of times? Accolades have been bestowed upon the B-series Honda at an almost embarrassing rate—and we might add that all of its praise is well deserved. But we have already begun to turn our attention to the newer K-series motors, which by all accounts are even better motors than the B-series. They are sure to start a revolution of their own, but that is a discussion for a different day.

What can we say about VTEC Honda motors that hasn’t already been said thousands of times? Accolades have been bestowed upon the B-series Honda at an almost embarrassing rate—and we might add that all of its praise is well deserved. But we have already begun to turn our attention to the newer K-series motors, which by all accounts are even better motors than the B-series. They are sure to start a revolution of their own, but that is a discussion for a different day.

Today we focus on the venerable B-series engine, including the more common B16A, B18A, B and C and C5 variants. These twin-cam VTEC (and hybrid) motors have powered the vast majority of winning sport compact machines over the last decade and they continue to be affordable and popular among both street and strip enthusiasts. Their immense popularity has spawned an entire industry, including the much-needed production of aftermarket blocks and high-performance cylinder heads. We’ll be taking a look at the new Dart B-series block in the next issue, but for now let’s examine the CNC-ported B18C cylinder head offered by Dart.

Today we focus on the venerable B-series engine, including the more common B16A, B18A, B and C and C5 variants. These twin-cam VTEC (and hybrid) motors have powered the vast majority of winning sport compact machines over the last decade and they continue to be affordable and popular among both street and strip enthusiasts. Their immense popularity has spawned an entire industry, including the much-needed production of aftermarket blocks and high-performance cylinder heads. We’ll be taking a look at the new Dart B-series block in the next issue, but for now let’s examine the CNC-ported B18C cylinder head offered by Dart.

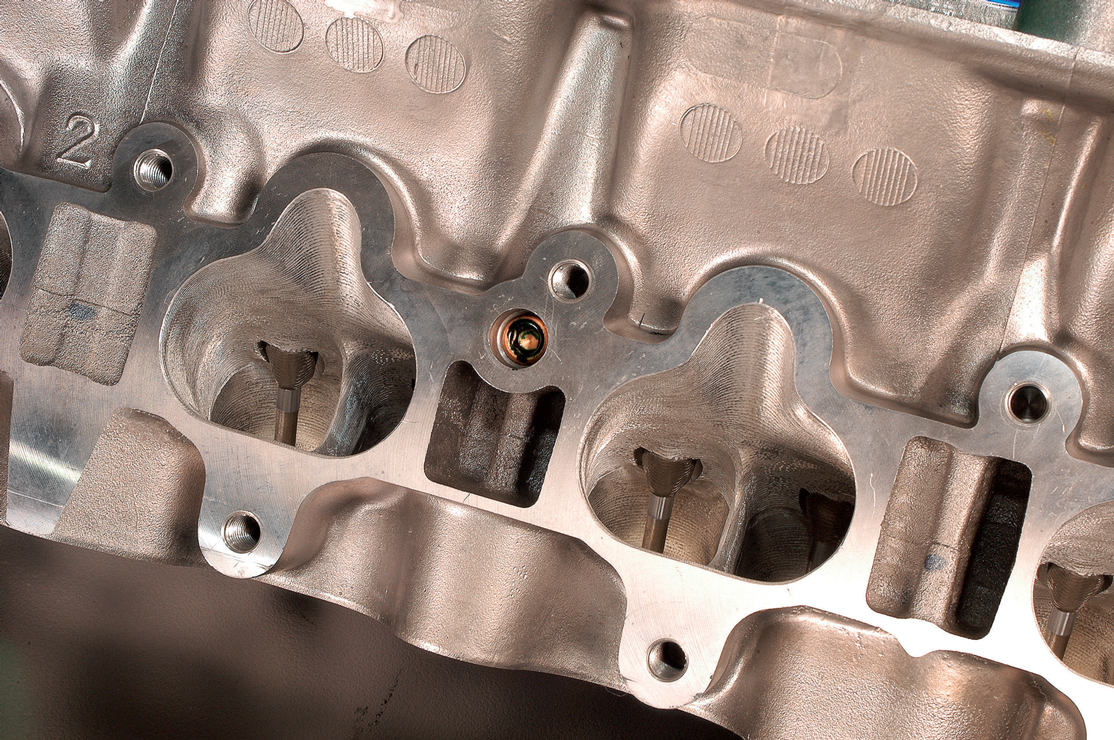

While the sophisticated, trick dual-cam profile VTEC systems receive much of the praise for the elevated specific outputs produced by small-displacement Honda motors, the reality is that no single component is actually responsible for allowing a production motor to reach or exceed the magical 100 hp-per-liter mark. How many manufacturers are still struggling to come to grips with the power outputs that Honda has been offering the performance public since 1989? Sure, the dual-cam VTEC system provides a Dr. Jekyll and Mr. Hyde personality by offering ultra-smooth idle, exceptional fuel mileage and impressive throttle response with a wicked top-end charge. But all the Jekyll-and-Hyde comparisons mean squat if you don’t have the airflow to back it up. By airflow we mean the intake manifold, the exhaust manifold and most importantly, the cylinder head. Often overlooked, one of the key ingredients in the performance of the twin-cam B-series motor is the impressive cylinder head.

The internal combustion engine operates most efficiently when the individual components are designed to operate effectively within a given rpm range. This means that the cam profile(s) must work with the intake design, the head flow and the exhaust system to produce optimum power (or mileage, depending on the design goal). If the B-series VTEC motor was saddled with a restrictive cylinder head, the power output would most certainly plummet. Ditto for the intake manifold, the exhaust manifold and even lesser components, like the air intake system. Just one component out of place and the whole combination will suffer greatly. Talk about your “one bad apple spoiling the whole bunch” scenario.

The internal combustion engine operates most efficiently when the individual components are designed to operate effectively within a given rpm range. This means that the cam profile(s) must work with the intake design, the head flow and the exhaust system to produce optimum power (or mileage, depending on the design goal). If the B-series VTEC motor was saddled with a restrictive cylinder head, the power output would most certainly plummet. Ditto for the intake manifold, the exhaust manifold and even lesser components, like the air intake system. Just one component out of place and the whole combination will suffer greatly. Talk about your “one bad apple spoiling the whole bunch” scenario.

Fortunately for Honda enthusiasts, its engineers seemed to understand this important fact more than most and they went out of their way to make sure every component on its wonderful VTEC motor plan was up to snuff. The fact that it is the only manufacturer to reach an amazing 120 hp-per-liter shows that Honda engineers fully understand the concept of integrated performance components.

As good as the stock components are, there are obviously ways to make them even better. Understand that this is no attack on the ability of Honda engineers; it is just that maximum power is never a design criterion for anything but an all-out race engine. Honda has shown that it can be competitive in any arena it cares to enter, despite the fact that it is struggling in Formula 1. Remember that not long ago Honda engines dominated even this top level of motorsports, so it is no stranger to absolute performance.

As good as the stock components are, there are obviously ways to make them even better. Understand that this is no attack on the ability of Honda engineers; it is just that maximum power is never a design criterion for anything but an all-out race engine. Honda has shown that it can be competitive in any arena it cares to enter, despite the fact that it is struggling in Formula 1. Remember that not long ago Honda engines dominated even this top level of motorsports, so it is no stranger to absolute performance.

The reason the factory motors suffer somewhat in terms of maximum power is that a number of design criteria went into the components other than elevated power levels. In addition to producing exceptional horsepower-per-liter, the production motors must also balance exhaust emissions, noise regulations and fuel economy. They must provide a broad torque curve, something obviously aided by the VTEC system, but that search for additional low-speed power has an effect on power production elsewhere in the power band. As good as they are, the production B-series VTEC motors are still very much a compromise, at least as far as maximum performance is concerned.

Cylinder head flow, along with a number of other important power-producing principles, helps determine the eventual power output of a motor. When it comes to improving the performance of your stock B-series cylinder head, great care must be taken. Though it is possible to improve the airflow rate and therefore eventual power potential of the B-series head, it is just as easy to lose power by hogging out what is already an excellent cylinder head design. The cold hard reality for some enthusiasts is that in their quest for more power they often wind up yielding even less than with the stock head, since porting can butcher what is already plenty of airflow.

This is especially true when working with the smaller B16A motor, which is more sensitive to oversized port volumes and lazy flow. Given that essentially the same head used on the 160hp B16A will easily support the 195hp larger B18C5, many enthusiasts would do well to simply leave the stock head alone, rather than risk ruining a perfectly good head by subjecting it to bad, hogged-out head porting.

This is especially true when working with the smaller B16A motor, which is more sensitive to oversized port volumes and lazy flow. Given that essentially the same head used on the 160hp B16A will easily support the 195hp larger B18C5, many enthusiasts would do well to simply leave the stock head alone, rather than risk ruining a perfectly good head by subjecting it to bad, hogged-out head porting.

Naturally, this wouldn’t be much of a story if the only information we had for you when searching for more B-series power was to leave your stock head alone. But it is important to understand that the stock head flows very well for what it is. Also understand that while hack porting can ruin a perfectly good Honda head, quality porting can just as easily improve upon it. The key is to have the right technician behind the tool.

In this case, the technician in question is actually a machine, as in CNC machine. Okay, so there is a person behind that machine. In fact, there’s an entire company behind it, which is the real key to success for the Dart Honda head. It is the precision and consistency offered by the CNC porting, as well as initial design going in, that separates the men from the boys.

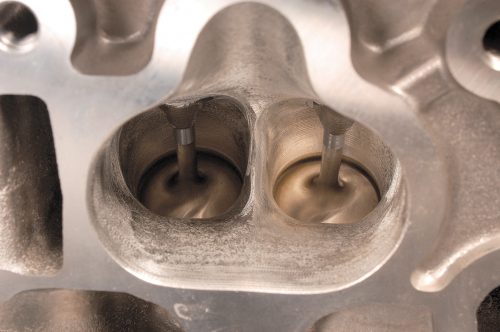

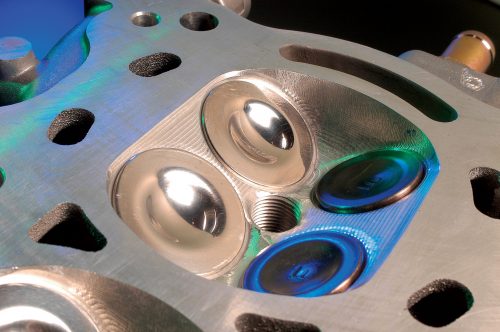

The term “CNC” stands for computer numeric controlled, a fancy name for a bunch of computer-controlled cutters that automatically go in and remove precise amounts of material to improve flow, without resorting to dramatic changes to the port volume or port-to-port configuration. The ideal port flows the most amount of air through the smallest opening, which has to do with creating velocity. Not surprisingly, bigger ports tend to flow more air, but the science and art of producing a good cylinder head is balancing the size-to-flow relationship while maximizing velocity.

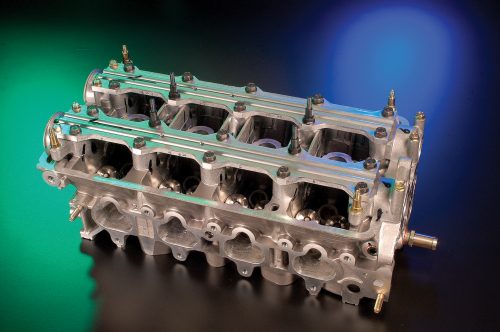

One of the benefits of the CNC porting is the ability to consistently reproduce the size, shape and flow rate of a given port. The problem with traditional hand-porting—besides the tremendous amount of labor involved—is that it is often difficult to reproduce a given port shape or flow rate (across the lift scale). Short of porting and airflow testing each port a dozen or more times during the process, it is difficult to ensure that all four ports will flow identically.

The idea behind maximum performance is to have all four ports flow the same and produce the same amount of power. This goes for intake flow, exhaust flow and injector flow, as well. By contrast, the CNC cutters, with the proper computer program, will produce the same port flow over and over again. The only potential problem is core shift, but even this can be accounted for in the program. The key to the success of CNC porting is initially producing a good hand-ported sample for the program to mimic. These first steps take time, but once perfected, CNC porting can spit out picture-perfect ports time after time.

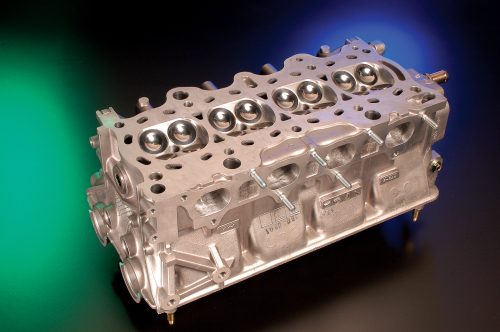

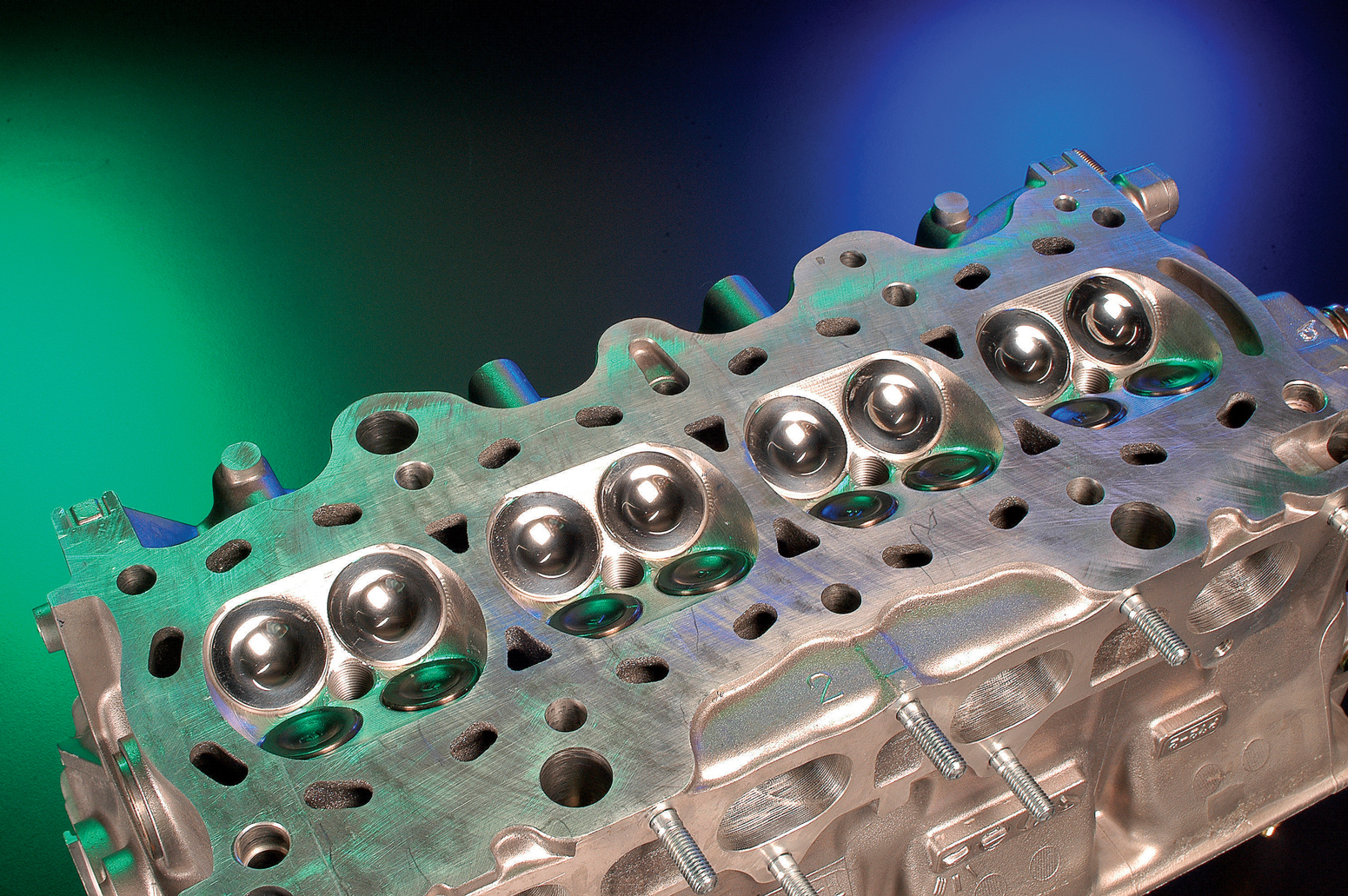

Dart, a name synonymous with performance cylinder heads for domestic applications, has now applied this CNC procedure to the already impressive Honda B-series cylinder head. The new CNC Honda head available from Dart starts out life as a new B18C (GSR) casting, which is then treated to precision porting and a number of other performance-enhancing upgrades. Obviously, Dart did its homework on the Honda head, as the new casting outflows the stock intake port by more than 30 cfm!

Now remember that unlike many domestic counterparts, the stock B18C GSR head was already an excellent cylinder head, so achieving flow gains of 30 cfm was quite difficult. Not that we don’t trust the guys at Dart—they are a quality bunch and owner Richard Maskin is well known for his championship-winning ways in the Pro Stock engine building ranks. But we verified those flow numbers on the SuperFlow bench and we can say for certain that the new CNC-ported Dart Honda head out-flows the stock head by a good 30 cfm on the intake and more than 40 cfm on the exhaust!

Now remember that unlike many domestic counterparts, the stock B18C GSR head was already an excellent cylinder head, so achieving flow gains of 30 cfm was quite difficult. Not that we don’t trust the guys at Dart—they are a quality bunch and owner Richard Maskin is well known for his championship-winning ways in the Pro Stock engine building ranks. But we verified those flow numbers on the SuperFlow bench and we can say for certain that the new CNC-ported Dart Honda head out-flows the stock head by a good 30 cfm on the intake and more than 40 cfm on the exhaust!

These are most impressive numbers, considering the fact that the formula for converting airflow to potential horsepower suggests that each additional cubic foot per minute is worth a hair more than 1 hp. Using this formula, the new CNC-ported Dart Honda head may be worth an additional 30 hp to 35 hp on the right combination, out of the box.

In addition to the flow rate produced by the CNC porting, the Dart head features a number of other worthwhile upgrades. To take full advantage of the additional flow offered by the Dart Honda head, it is necessary to run something other than stock B16A, GSR or even Type-R cams. The Dart Honda head comes with revised intake and exhaust valve springs to allow the installation of wilder cams. Included in our casting was a full complement of Ferrea stainless steel valves and titanium retainers. The lightweight retainers further increase the rpm ability of the already rev-happy B-series motor.

In addition to the flow rate produced by the CNC porting, the Dart head features a number of other worthwhile upgrades. To take full advantage of the additional flow offered by the Dart Honda head, it is necessary to run something other than stock B16A, GSR or even Type-R cams. The Dart Honda head comes with revised intake and exhaust valve springs to allow the installation of wilder cams. Included in our casting was a full complement of Ferrea stainless steel valves and titanium retainers. The lightweight retainers further increase the rpm ability of the already rev-happy B-series motor.

The engineers at Dart were sharp enough to recognize a good thing when they saw it, so they left many of the stock features on the head alone. This list included the intake and exhaust port locations, critical valve specs and required gaskets. The stock specs allowed use of all-factory, GSR-based intake manifolds, all B-series headers and the complete factory valvetrain. In short, Dart improved where improvement was necessary, but it was wise enough to leave the rest alone.

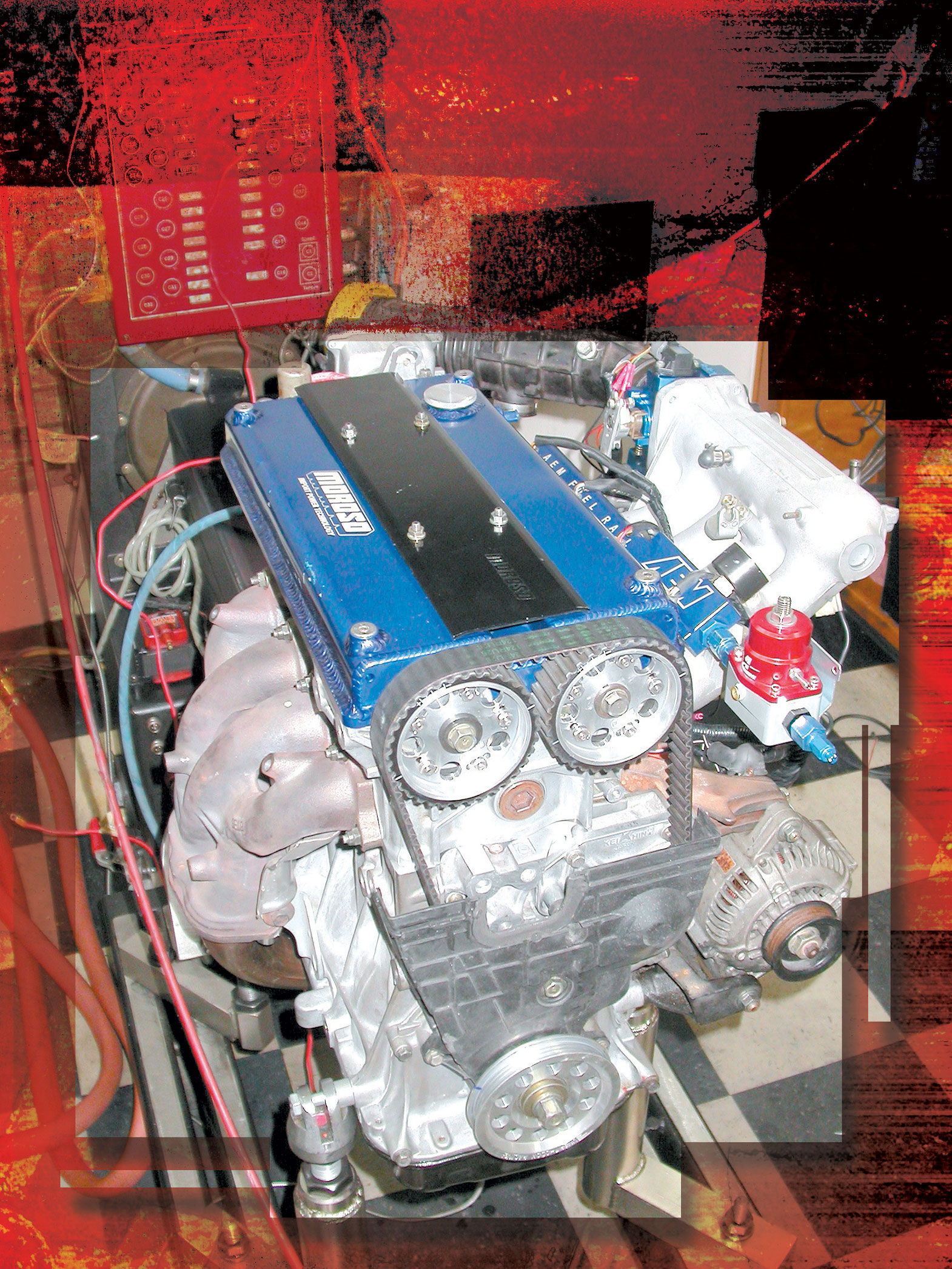

Loyal AutoBuilder readers will remember that we used a Dart CNC Honda head on our 650hp Turbo B18 buildup (“Ballistic B-Series,” Jan. ‘04, p. 41). The Dart head was selected because of its exceptional flow rate and port-to-port consistency. Even when running a turbo, the best way to produce big power is to start with an efficient, normally aspirated motor. The airflow-to-power formula (horsepower = airflow x 0.257/number of cylinders) suggests that the Dart Honda head is capable of adding a good 30 to 35 hp over a stock head. Even using our conservative flow bench numbers, the Dart head would support a 285hp normally aspirated B-series. You’re not likely to run across too many 285 all-motor B-series on the street (or anywhere else), but it is nice to know that the Dart head can help you get there, should you decide to go more radical on the rest of the combination.

The best part about the new Dart Honda head is that it bolts right on, just like a stocker (since that is what it once was), but with all new castings and components. Given the ease of installation, the impressive flow numbers and the hefty horsepower potential, we’d say Dart’s Honda head has hit the proverbial performance bull’s eye.

The best part about the new Dart Honda head is that it bolts right on, just like a stocker (since that is what it once was), but with all new castings and components. Given the ease of installation, the impressive flow numbers and the hefty horsepower potential, we’d say Dart’s Honda head has hit the proverbial performance bull’s eye.