4.6-Liter Ford Blower Cams

One of the most misunderstood performance components on any engine has to be the camshaft, or camshafts in the case of our overhead-cam 4.6-liter Ford engine. The difficulty is only compounded when you add forced induction to the mix. From an anatomical standpoint, the camshaft can be likened to the brain, as the cam profile determines how effectively (when and where) breathing takes place. The camshaft is one of the major determining components of the effective operating range of the engine. Of course, the cam timing must be combined with the proper intake manifold, head flow and primary length on the exhaust for optimum operation over a given rpm range—but the right cam can almost determine the character or personality of the engine. A stock or ultra-mild aftermarket cam will provide a dead-smooth idle, while a more radical grind can transform that mild-mannered engine into one radical ride. The radical-ride route usually includes ill-tempered, cantankerous behavior until the engine comes on the cam, but such is the price for all that high-rpm heaven.

Many enthusiasts at least understand the basics of cam timing. They realize that a so-called Saturday-Night Special grind is much wilder and potentially more powerful than the production cam profile. The problem arises when deciding to choose between these two extremes, especially for a daily driver. The temptation is certainly there to go BIG on the cam profile; after all, isn’t bigger always better? The problem with going big is twofold. The first problem is that the cam profile must be selected not for bragging rights at the drive-in (or coffee house), but rather to work with your existing components. Adding the right cam to your otherwise stock engine can result in impressive power gains. Adding a wild cam to your otherwise stock engine will likely result in a drop in power throughout most of the rev range and can actually decrease peak power since the cam was designed to run effectively at 6,500 rpm, and the rest of your stock components (intake runner length, head and exhaust flow) sign off at just 5,000 rpm.

As a general rule, the closer to stock the remainder of the components, the milder the cam profile that should be chosen. This means leave those weekend-warrior cams to the drag racers and stick with a mild but effective profile that will offer power gains not just at high rpm but throughout the rev range. After all, what good is it to add 25 hp at the power peak, only to lose 35 lb-ft down at 3,000 rpm? Think for a moment about where (what rpm) you spend most of your time driving and choose a cam accordingly!

Pick up just about any book on the subject of forced induction and skip to the chapter or section on camshafts. More than likely, the recommendation will be to run stock cams or at least stay away from the dreaded duration or overlap that can cause all that precious boost to escape out the exhaust valve. While blowers (and turbos) work fine on stock engines equipped with stock cam profiles, they (just as with normally aspirated engines) respond very well to more aggressive cam timing. In fact, for most street applications, the camshaft chosen for a mild normally aspirated engine will work equally well with a supercharger. Sure, you can tailor the specific cam timing for supercharged use, but the gains will be minimal at most mild boost and power levels run on the street (compared to a normally aspirated performance cam).

This is actually good news for enthusiasts, as choosing the right cam for a blower motor is actually as easy as selecting one for a normally aspirated engine, and in many cases is actually the very same cam. Generally, manufacturers list applications for their cams, and many have included profiles for forced-induction engines, but those intended for naturally aspirated engines work well, too. Rather than go on with more conjecture and theory, we thought it would be a good idea to illustrate the benefits of a mild (street-oriented) cam profile on a supercharged application. In fact, we went one (actually two) better by illustrating the benefits of the supercharger itself, the effect of additional boost pressure and then the effect of wilder cam timing on both the boost and power curves.

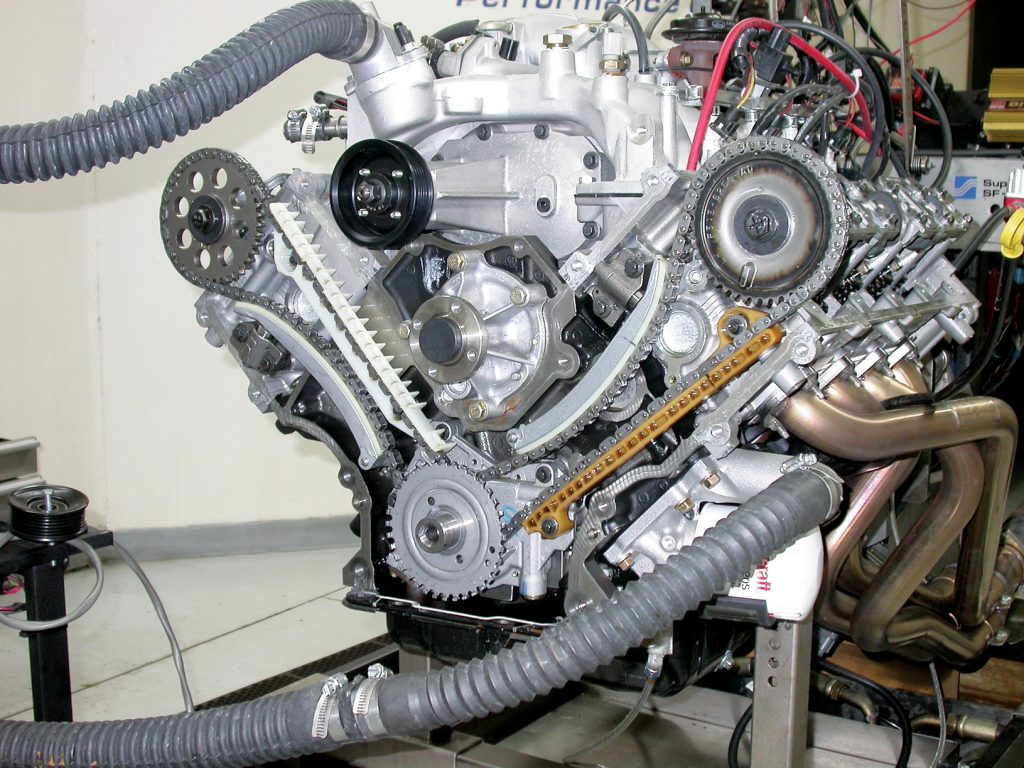

The test engine consisted of a two-valve 4.6-liter GT engine provided by Sean Hyland Motorsport. The Sean Hyland Motorsport (SHM) 4.6-liter was of the more desirable (‘99 and up) Power-Improved (PI) version. The SHM engine featured a forged reciprocating assembly (but stock compression) topped off with bone-stock PI heads, cams and composite intake manifold. Waiting in the wings was a Ford Racing supercharger assembly consisting of an M90 Roots supercharger and dedicated aluminum intake casting. The supercharger assembly featured long-intake runners designed to optimize power (and torque) production up to 6,000 rpm. Obviously, the supercharger would provide the additional airflow in the form of boost pressure, but the intake runner length is critical (in both NA and blown applications) for maximizing torque production. Combining the immediate boost response of a positive-displacement (Roots) blower with optimized runner length makes for one impressive power curve.

In addition to the blower, we also had a larger throttle body, an additional (smaller) blower pulley to increase the boost pressure, as well as a pair of Comp Xtreme Energy XE262H cams that would reduce the boost pressure but ultimately increase power. Did we say more power with less boost? That’s right, improving the efficiency of the engine will result in a drop in boost to go along with the increase in power—basically the best of both worlds.

The SHM 4.6-liter GT engine was installed on the engine dyno and equipped with 36-lb injectors run by a FAST engine management system. The injector size was chosen in anticipation of the Ford Racing supercharger, increased boost and cam upgrade. The SHM 4.6-liter engine was equipped with a set of Kook’s 1-5/8-inch stainless steel headers (for late-model 4.6-liter Mustang GT applications), an electric water pump and an MSD coil-pack. The FAST system was tuned to provide 28 degrees of total timing and offer a (WOT) air/fuel ratio of 13.0:1. Equipped with a 3-inch open exhaust and the stock 65mm throttle body, the 4.6-liter produced 298 hp at 4,900 rpm and 345 lb-ft of torque at 4,100 rpm. The difference between the 260hp factory Ford rating and the 298 hp achieved on the dyno can be attributed to the difference in test methods. The 260hp rating by Ford was achieved with full accessories, full exhaust and a complete inlet system. Our test engine featured no accessories, an open exhaust and a free-flowing inlet system. As expected of the stock engine, the power fell off rapidly after 5,000 rpm and was down by 35 hp at 5,900 rpm. The 4.6-liter exceeded 310 lb-ft of torque from 2,500 rpm to 5,100 rpm but dropped off to just 238 lb-ft at 5,900 rpm.

After our baseline numbers were established, we installed the Ford Racing supercharger. On the dyno, the blower install was no more difficult than an intake swap. We replaced the Meziere electric water pump with the factory unit, as we had to utilize the water pump pulley to properly guide (and tension) the blower belt. The Ford Racing supercharger was equipped with the stock 65mm throttle body and the supplied 3.6-inch blower pulley. The total timing was dropped to 18 degrees (to run safely on 91-octane fuel) and the air/fuel mixture was richened up to 11.8:1. Equipped with the Ford Racing supercharger, the SHM 4.6-liter produced 383 hp at 5,700 rpm at a peak boost pressure of 6.8 psi.

It is important to point out that the boost pressure supplied by the Ford Racing blower was pretty consistent from 2,500 rpm to 5,000 rpm, offering between 4.5 and 5.2 psi. Only after 5,000 rpm did the boost start to stack in the manifold due to the mild cam timing and restrictive head flow of the stock PI heads. The long-intake runners and immediate boost pressure offered by the Roots blower made themselves known by adding an extra 50 lb-ft of peak torque (from 345 lb-ft to 395 lb-ft). The Ford Racing blower even upped the torque output by 60 lb-ft at just 2,500 rpm.

The final modifications included a larger throttle body, a smaller blower pulley and the Comp Xtreme Energy cams. Adding the Ford Racing 70mm throttle body resulted in a jump in power from 383 hp to 394 hp, a gain of 11 hp. The airflow improvements offered by the larger throttle body actually increased the boost pressure supplied by the Ford Racing blower by 0.2 psi. As expected of changes in airflow to the blower, the power gains increased with engine speed, starting at 3,400 rpm and increasing until 5,900 rpm. The larger throttle body was responsible for an extra 7 lb-ft of torque.

Next up was the blower pulley upgrade from South Florida Pulley Headquarters. The smaller blower pulley (from 3.6 inches to 3.4 inches) upped the peak boost to 8.8 psi but offered an additional 1 to 1.5 psi through most of the rev range. The small increase in boost pressure resulted in gains throughout the rev range, upping the peak power from 394 hp to 405 hp. The torque was now up to 417 lb-ft (from 402 lb-ft with the 70mm throttle body). Like the previous runs with the Ford Racing supercharger, the boost curve was pretty consistent up to 5,000 rpm, increasing rapidly thereafter. The increase in blower speed exaggerated the boost stacking in the manifold.

The final modification involved swapping out the stock PI cams for a set of Xtreme Energy 262H cams. We originally wanted to install the XE262AH cams designed for the later PI heads, but lack of preparation by the author caused us to switch to plan B and install the XE262H cams designed for the early non-PI heads. The main difference between the PI and non-PI cams was the lift value. The PI heads were set up to accept higher (0.550-inch) lift cams than the non-PI (0.500-inch lift) versions. The non-PI cams can be run in the PI heads with no trouble, but the reverse is not true without taking the necessary measures to ensure adequate retainer-to-seal and coil bind (valve spring) clearance. The XE262H cams offered 0.500-inch lift (both intake and exhaust) but a dual-pattern duration split. The intake featured 224 degrees of duration (at 0.050-inch) and 232 degrees of exhaust duration. The wide 114-degree lobe separation angle ensured a broad curve and a relatively smooth idle given the durations’ specs. The 262 cams were the smallest profiles offered by Comp for the two-valve 4.6-liter GT engines. The Xtreme Energy cams worked fine with the stock valve springs, although Comp does offer a valve spring upgrade for both the two-valve and four-valve modular motors.

Installing the cams was not terribly difficult, since we had already performed the procedure at least a dozen times. The XE262H cams have been previously tested on a modified normally aspirated engine and shown to offer impressive power gains on the order of 30 to 35 hp. How well would these “normally aspirated” cams work on our blown 4.6-liter? Well, the answer is that they worked equally well on this supercharged application, as the Comp cams upped the peak power from 405 hp to 436 hp (both at 6,000 rpm). In fact, the Comp XE262H cams not only improved the peak power and torque numbers, but they showed well by not losing power anywhere to the stock PI profiles. Even down at 2,500 rpm, the Comp cams equaled the power output of the stock PI cams. It is interesting to note that when tested normally aspirated, the Comp cams showed power improvements starting at 4,500 rpm, but the gains on this supercharged application started as low as 3,300 rpm. Installation of the cams actually reduced the peak boost pressure to just 6.9 psi. The drop in peak pressure is not from boost escaping out the exhaust of the wilder cam timing but rather from the increase in efficiency. The more powerful the normally aspirated engine, the lower the boost pressure at any given blower speed. There you have it: a real-world example where boost pressure and power are inversely proportional—sometimes less really is more!

Article Sources

FAST (Fuel Air Spark Technology)

901/260-3278

3406 Democrat Rd. Memphis, TN 38118

Kook’s Custom Headers

866/586-5665

59 Cleveland Ave. North Bayshore, NY 11706

Sean Hyland Motorsport

519/421-2291

691 Jack Ross Ave. Woodstock, ON N4V 1B7

South Florida Pulley Headquarters

772/468-3585

P.O. Box 4443 Fort Pierce, FL 34948