Engine

Jack Fuller has been at this hot rod game for a long time, and while he builds hot rods for a living, make no mistake—this is a man who loves his work. As a matter of fact, the mantra of the garage is, “When the fun stops, the doors close for good.” It’s pretty simple stuff, and oddly enough, that seems to be the specialty of the house—basic hot rods that look cool and work well. Jump in a Jack Fuller hot rod, and you’ll know it was designed to be driven. Jack’s own ’32 cabriolet has seen untold miles over the years, as have most of the other hot rods he has built.

Fluids are the lifeblood of the vehicle. We need to contain those fluids yet still be able to monitor the fluid levels. Our older readers can remember the days before aftermarket flexible dipsticks or silicone caulk were available. The only option in those days was to use an OEM dipstick and dipstick tube. If you needed to shorten the tube, a hacksaw was the tool of choice. If you cut 4 inches off the tube, you then cut 4 inches off the dipstick and ground a couple of notches in the side of the dipstick to note “full” and “add.” Gaskets could be sealed with Permatex, but they had to be used as there was no such option of placing a bead of silicone caulk on the mating surface and assembling the parts.

When Ford introduced its Y-block engine in 1954, it labeled the engine the worthy successor to the venerable Flathead. The Flathead gained a loyal following of hot rodders and racers, but the big Cadillac overhead-valve V-8 and Oldsmobile’s Rocket 88 were stealing Ford’s thunder in terms of power, so something had to be done, and Ford decided to respond. The answer was a clean-sheet V-8 design, featuring overhead valves and improved cooling compared to the old Flathead. It was dubbed the “Y-block” because of the way it looked and because of its deep skirt and tall cylinder heads.

Hot rodders are a picky lot; some want their rides to look as if they stepped out of a time warp, but they also want them to be equipped with the latest of mechanical improvements. Disc brakes, power steering, air conditioning and even full surround-sound stereos and videos are the norm. So it should come as no surprise that the benefits of electronic fuel injection have been fully embraced by those who drive vintage trucks. But with notable exceptions, the look of the fuel injections systems was mostly unpleasing to the eye.

The relentless progress of technology is a difficult topic for those of us captivated by the cars and lifestyles of a bygone era. As technology advances at an exponential rate, we now find ourselves clamoring to keep up with the latest and greatest products that simultaneously render many of our old favorites obsolete. Just about the time you figure out how to use your new digital camera and multifunction cell phone, you find out that someone decided it was necessary to combine the two. The struggle to balance the conveniences of modern technology with our nostalgia is especially difficult for many street rodders.

Until now, rodders have been severely limited by the battery-charging alternators they’ve had to select from. Rodders either utilized an OE or an OE-style alternator for their custom engine applications, or they selected one of the aftermarket units that were polished or chromed. Now, with the introduction of MSD’s Advanced Power System (APS) alternator, that’s all changed for the better.

The showroom is what every auto parts store dreams of being: diced in checkerboard black and yellow tile with a heap of pegboard. Up front, the sales counter is the hub of business, fueled by eager customers that keep the phone ringing off the hook. Bob, Sam and Robin deal one-on-one with customers, keeping all 50 states Moon-equipped.

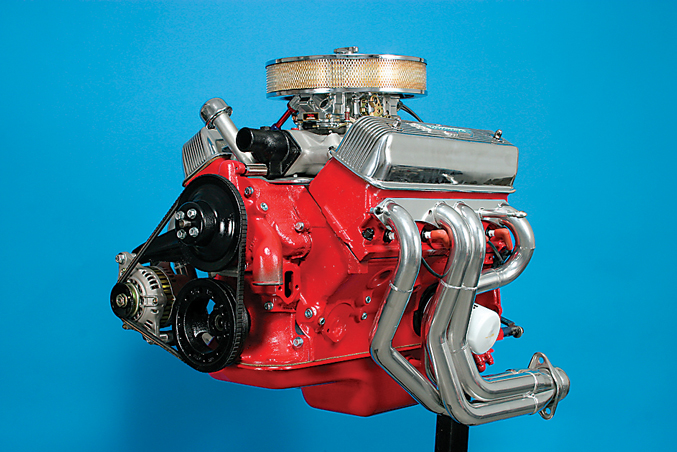

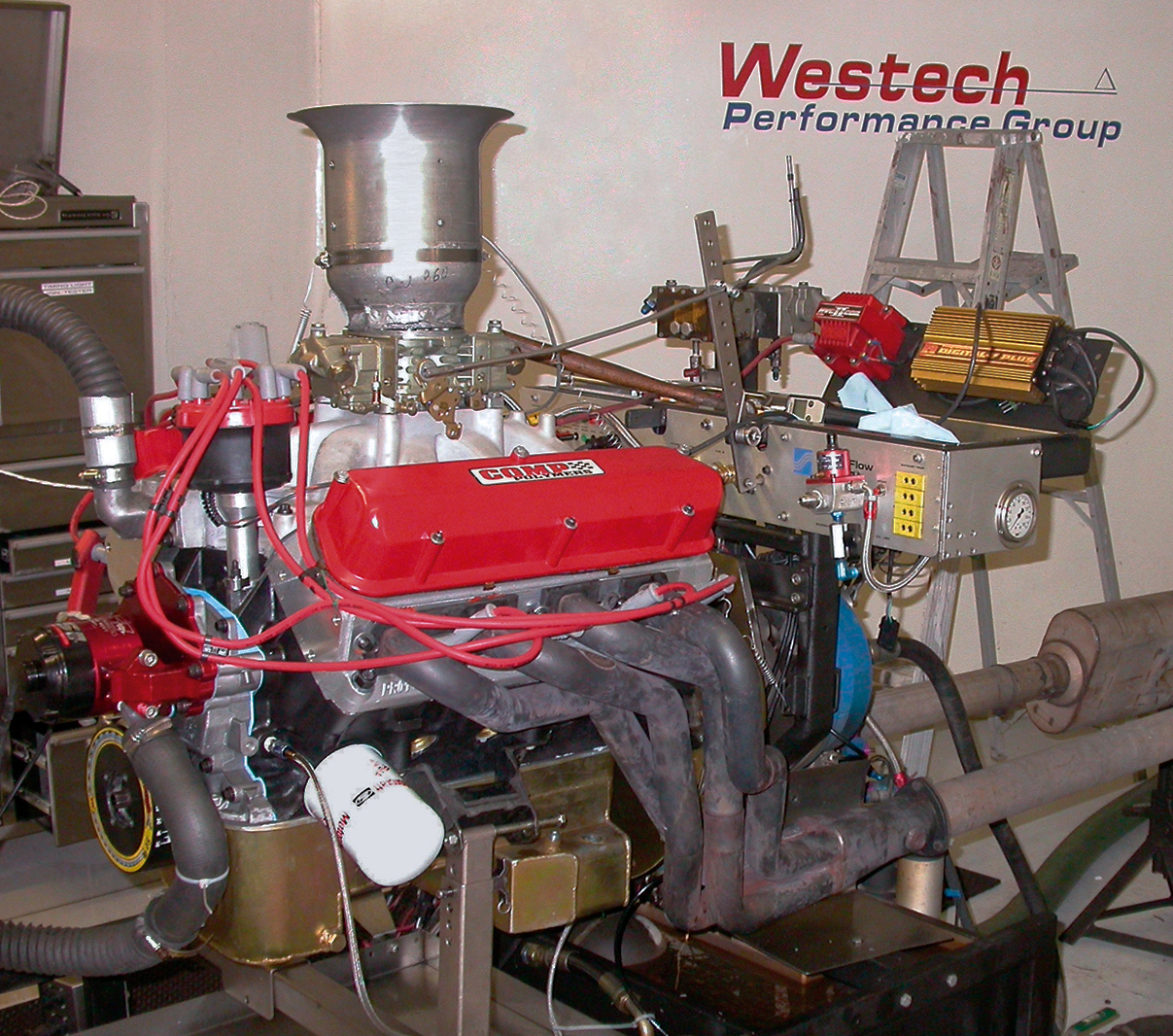

Producing horsepower requires two major ingredients, namely, air and fuel. Of course, the two must be supplied in the correct proportions and at the proper time; but improving power is a simple matter of adding airflow. Naturally, additional fuel will be required once the airflow is improved, but the first item on the horsepower priority list should always be more airflow.

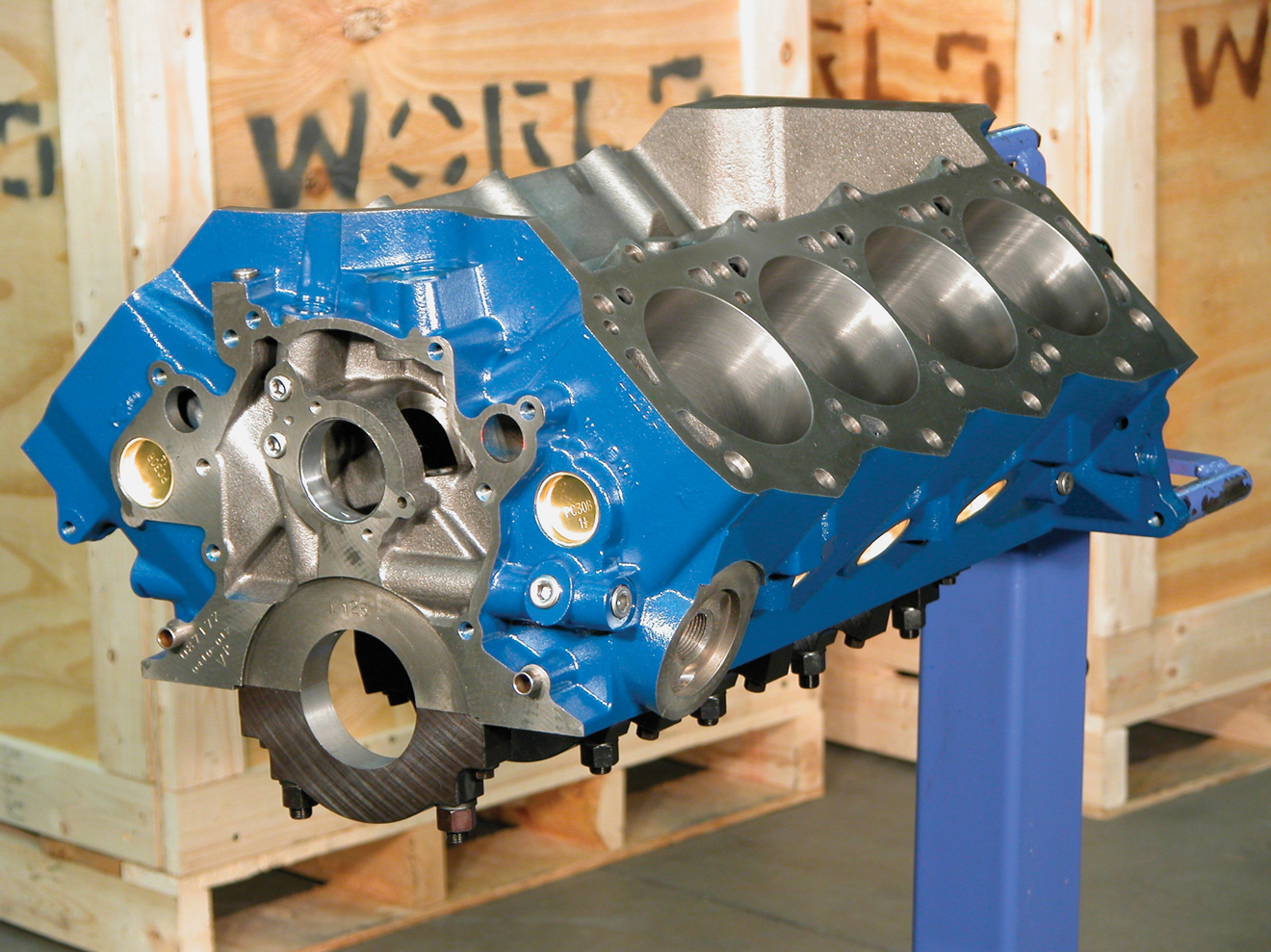

While the small-block Chevy is the popular engine choice for many enthusiasts, many are now relying on a Blue Oval heart for their performance bodies. With its link to Ford, the original body manufacturer for many of the classic cars we see today, the small-block Windsor-style Ford engine offers several advantages. When compared to Chevy, the lack of firewall clearance for a number of Chevy engine swaps is due to the rear distributor position of the engine. The front-mount distributor position is the more logical place to drive the distributor and the oil pump. Not to mention, it’s much more convenient.