Exterior

There are many reasons why the icon cars have achieved the lofty status they now enjoy, but one of the more obvious reasons is the simple fact that they were finished. Their existence and subsequent high-level exposure have inspired many a young lad to undertake similar projects, and for every famous car built in the early years, probably two others were started in an attempt to either copy or outdo it, but they never saw the light of day.

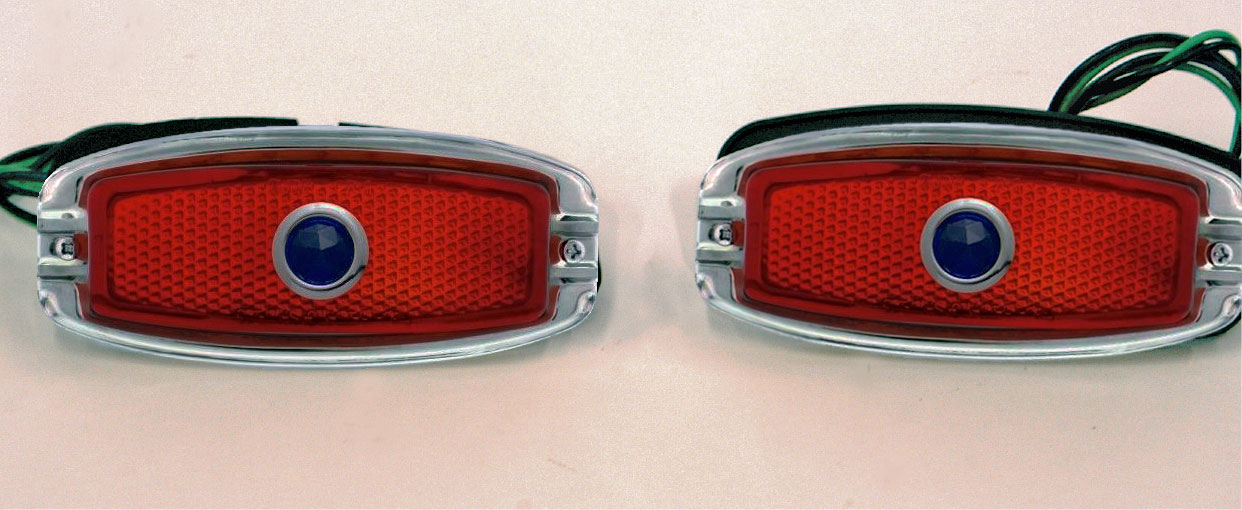

If you are building a street rod, sooner or later you will have to select the taillights you want to use. As with so many other parts, the taillights should match the style of the car you are building. A smooth, high-tech rod should have taillights of the same style, perhaps flush-fit diode lights that match the shape of the body. If you are building a resto rod, the stock taillights are generally used, stalk and all. Internally they can be updated with bright bulbs or a diode kit. If you are building a nostalgic or a traditional rod, there are several different lights that were used by builders in the ’50s and the ’60s. The rod seen in this story is being built in a traditional style, so there were many lights to choose from.

For every hot rod shop that has a show on TV, there are countless smaller shops that will never get mainstream TV exposure or clothing lines sold at Wal-Mart. But all across the country, it’s these smaller shops that turn out the majority of the street and super rods that you and I enjoy, and that we see at shows. And even though these little guys may not have big reputations yet, they churn out consistent and excellent work—and, that is precisely how some of these smaller shops will eventually become bigger shops with even more prestige.

Using the traditional lead method for body repair is a dying art but, for the traditionalist, it’s still the best method to use.

When building a street rod there are a great many facets of the construction process that go into making the car an award-winning creation. First, there’s planning. The planning of the car can and should include attention to each and every area of the car, from concept to reality. Even the most basic of projects should have the proper planning involved, no matter what the final product might be. Once work has begun on the project, countless hours are generally involved in attending to every detail. From making the many modifications to the chassis to attain the desired drive train, to the matching and mating of the different components together, this becomes an involved process requiring a great deal of skill in fabrication and engineering.

When the engineers at Chevrolet designed the fuel inlet and fuel cap for the early Nova, they must not have looked at the rest of the car. Novas aren’t called shoeboxes for no reason; with the exception of the wheels–and that gas cap–they are basically square. Wheels have to be round, but the gas cap, well….

With tech and how-tos that might benefit you for both street and/or strip application. Sometimes those elements are major, other times they are far less significant, but nonetheless helpful. We also pay particular attention to things that are of interest, up to and including the reasons why an owner did not win at a car show. There are 55 photos here, each with a bit of info. Many may pay dividends for you sometime in the future, so sit back, learn, laugh and enjoy.