Creating the best needs all the pieces...

When building a street rod there are a great many facets of the construction process that go into making the car an award-winning creation. First, there’s planning. The planning of the car can and should include attention to each and every area of the car, from concept to reality. Even the most basic of projects should have the proper planning involved, no matter what the final product might be. Once work has begun on the project, countless hours are generally involved in attending to every detail. From making the many modifications to the chassis to attain the desired drive train, to the matching and mating of the different components together, this becomes an involved process requiring a great deal of skill in fabrication and engineering.

Many more hours are generally spent making changes to the exterior appearance by moving, adjusting and manipulating body panels for that special look that can only be obtained through years of experience, trial and error, and in some cases, just plain luck. No matter which course of action has been taken, the bottom line is that a lot of time and effort has gone into the building of the car.

Once all the chassis and body modifications are completed, there can be just as much work involved in the painting, plating and polishing of all the individual components for the proper finish. That proper finish becomes the signature for the work performed. With today’s close tolerances on fit and finish, assembling all the components without doing harm to that perfect finish has become one of the defining steps in building an award-winning car.

Now if the proper planning mock-up went into the buildup of the car, one knows that all of the parts fit perfectly prior to being disassembled. And when those parts go back together for the final time, they should fit back together with ease, just like the pieces of a jigsaw puzzle. That statement would be very profound, if it were only true. But our experience tells us otherwise, as we all know that certain parts simply will not go back together as smoothly as planned. The final assembly always requires the most patience and planning of all. Again, years of experience will teach us to expect complications, and to be prepared for them.

This process goes on in almost every shop, and in all parts of the country, week in and week out. Each time a car goes into the final assembly process, certain steps are followed, however. Each shop has its own way of final assembling a car, just as they have their own way of building a car from the beginning. Before this year’s Ridler Award competition in Detroit, we had the opportunity to be following along with two of the builders that made a great run at the Ridler. Both T&T Customs in Canton, Georgia, and Greening Auto Company in Cullman, Alabama, had vehicles that were detailed to a degree that would have defied logic only a few short years ago. But this level of work and attention to detail has become the standard to which all builders now strive to duplicate. And each year the bar is raised, to even higher levels.

While following the construction projects in these two shops, we discovered some of their secrets to keeping the various components from some of the pitfalls all of us have encountered at one time or another, while attempting the final assembly of all the parts on our cars. While some are simply common sense, it never hurts to pay attention to the tips from the pros. These builders do this for a living and they have mastered the art of their artful process, and their experiences can help each of us achieve a higher level of success with our own cars. We are grateful to T&T and the Greening’s, for allowing us to pass on to you their tricks of the trade. They were gracious to invite us into their shops to help spread the word. If you appreciate what they have done, feel free to give them a call and express your appreciation for their efforts. It is because of shops like theirs that our hobby has grown to the extent it has, and our cars have reached the level they have. Enjoy.

Use Protective Padding

When using jackstands, place a soft rag over the metal support. Wrapping some foam padding around the support first will add even more protection. Applying tape around the padding will hold it in place and make sure it does not slip off the stand. You do not want to put too much padding over the stand because the shape of the support bar can be distorted. This could lead to the frame slipping off the stand.

When using jackstands, place a soft rag over the metal support. Wrapping some foam padding around the support first will add even more protection. Applying tape around the padding will hold it in place and make sure it does not slip off the stand. You do not want to put too much padding over the stand because the shape of the support bar can be distorted. This could lead to the frame slipping off the stand.

Tape It!

Using 3M green automotive masking tape in places where sharp edges meet will protect the part from scratching. In this case, it was where the Model A splash apron meets the running board support arm. These parts can move while being installed. Place the tape over a large enough area to guard against any movement that can occur. Once the parts are securely tightened in place, the tape can be easily removed assuring that the paint was not scratched. The green tape works well along the edges of hood sides, doors, fenders, grille shells and any flat panels.

Using 3M green automotive masking tape in places where sharp edges meet will protect the part from scratching. In this case, it was where the Model A splash apron meets the running board support arm. These parts can move while being installed. Place the tape over a large enough area to guard against any movement that can occur. Once the parts are securely tightened in place, the tape can be easily removed assuring that the paint was not scratched. The green tape works well along the edges of hood sides, doors, fenders, grille shells and any flat panels.

Lay Some Carpet

Here is a trick Jesse Greening uses when assembling a chassis. Pick up a piece of remnant carpeting from a local carpet dealer or home supply store. It is usually pretty cheap and works well for several points. First, you will be working on a clean surface. Second, the carpeting provides a comfortable surface to be laying and crawling on while installing the components. The carpet will provide some protection to any parts that might otherwise be dropped or simply placed onto a hard concrete surface. Once the build is complete, the carpet can be cleaned, rolled up and reused again on the next project.

Here is a trick Jesse Greening uses when assembling a chassis. Pick up a piece of remnant carpeting from a local carpet dealer or home supply store. It is usually pretty cheap and works well for several points. First, you will be working on a clean surface. Second, the carpeting provides a comfortable surface to be laying and crawling on while installing the components. The carpet will provide some protection to any parts that might otherwise be dropped or simply placed onto a hard concrete surface. Once the build is complete, the carpet can be cleaned, rolled up and reused again on the next project.

Organize Your Parts

During the build and assembly of Steve Tracy’s completely chromeplated ’32 Ford chassis, Tracy stored the bolts as they were plated on a table in his office. The different sized bolts were grouped together, so he could keep track of which bolts, nuts and washers had been completed, and which ones were still to be scheduled. As it turned out, it was a great way to store them until they were needed for the assembly process. When a particular bolt and nut was needed, all he had to do was go to the table and pick it up. When an assembly process is pending, this same procedure could save you time hunting all those various-sized bolts and nuts by having them arranged and ready to retrieve. It all works with just a little thinking ahead.

During the build and assembly of Steve Tracy’s completely chromeplated ’32 Ford chassis, Tracy stored the bolts as they were plated on a table in his office. The different sized bolts were grouped together, so he could keep track of which bolts, nuts and washers had been completed, and which ones were still to be scheduled. As it turned out, it was a great way to store them until they were needed for the assembly process. When a particular bolt and nut was needed, all he had to do was go to the table and pick it up. When an assembly process is pending, this same procedure could save you time hunting all those various-sized bolts and nuts by having them arranged and ready to retrieve. It all works with just a little thinking ahead.

Organize as you Go

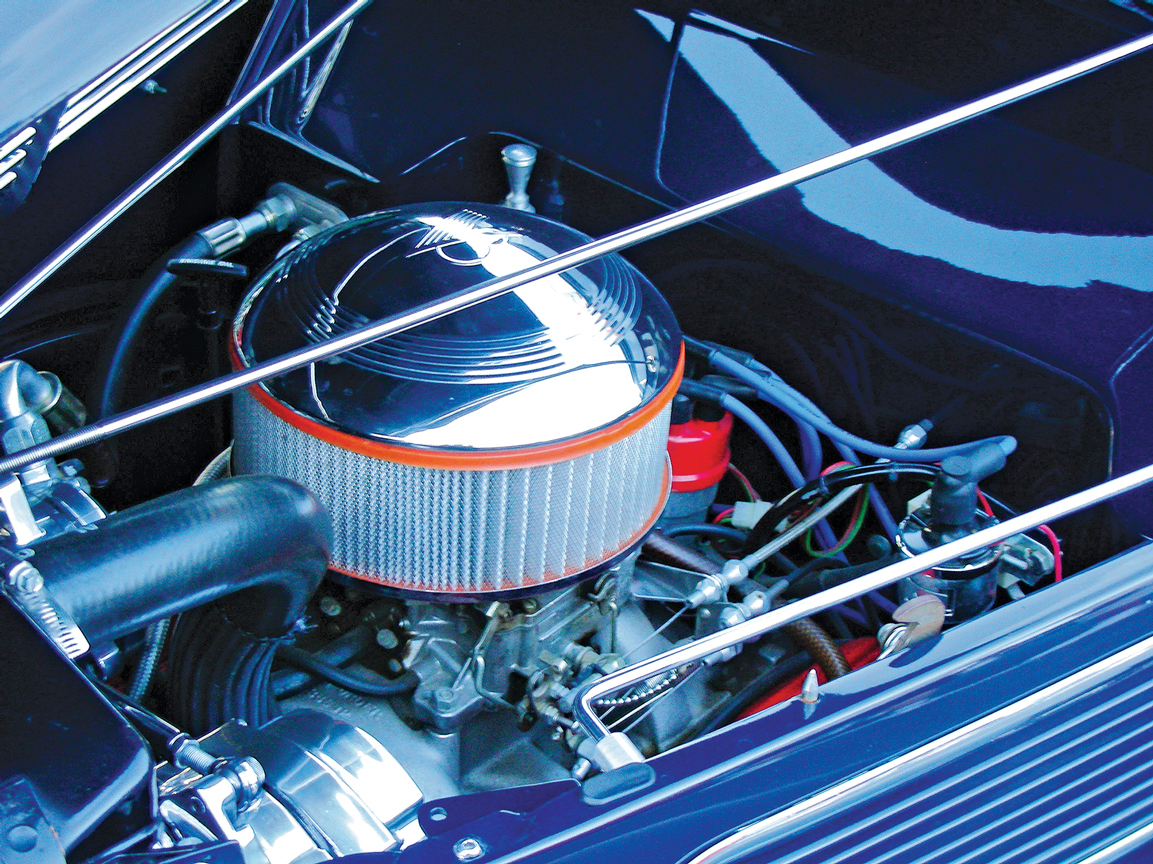

As certain components are assembled, they also can be stored and grouped together. Items such as front and rear suspension, engine components and brackets can be laid out so access to each component is easy. A table makes the best storage area for parts that are not too heavy. You should use a covering of some kind to lay the parts on. Again this is for protection of the parts and it also just looks more organized.

As certain components are assembled, they also can be stored and grouped together. Items such as front and rear suspension, engine components and brackets can be laid out so access to each component is easy. A table makes the best storage area for parts that are not too heavy. You should use a covering of some kind to lay the parts on. Again this is for protection of the parts and it also just looks more organized.

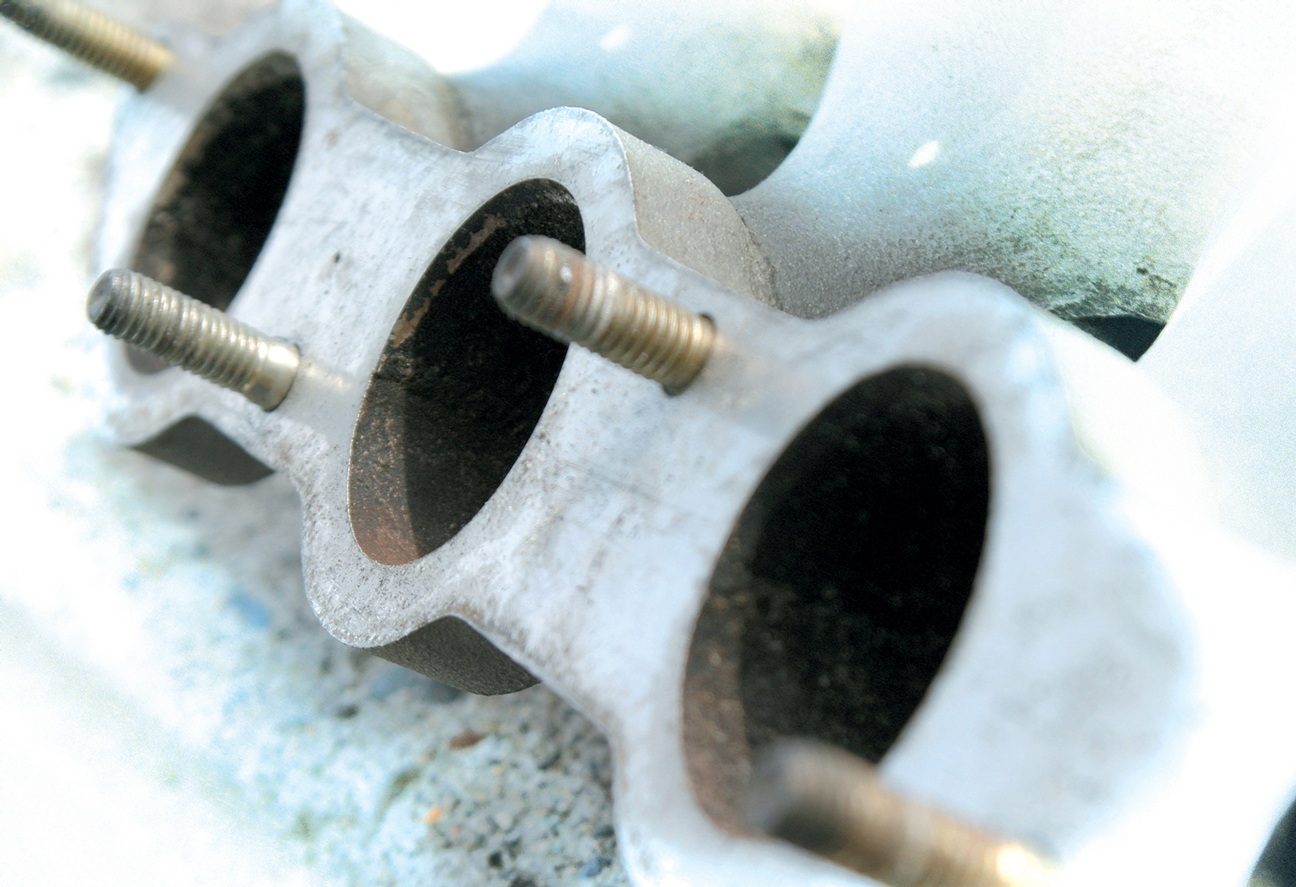

Tap It!

Before installing any bolts into a hole that has been painted, polished or plated, first run a tap into the hole. This will clean out any overspray, dirt, polishing compound or debris that could clog or cause damage to the threads (in the hole). Once you have “cleaned” the hole with the tap, use an air hose to thoroughly blow out the debris you created. Use of a cloth could lead to scratches from any metal filings that might be left from the tap. Once the hole has been blown out, spray the air all around the area of the hole to further remove any dust and debris.

Before installing any bolts into a hole that has been painted, polished or plated, first run a tap into the hole. This will clean out any overspray, dirt, polishing compound or debris that could clog or cause damage to the threads (in the hole). Once you have “cleaned” the hole with the tap, use an air hose to thoroughly blow out the debris you created. Use of a cloth could lead to scratches from any metal filings that might be left from the tap. Once the hole has been blown out, spray the air all around the area of the hole to further remove any dust and debris.

Cover Often

Again, we cannot emphasize enough that you cover any prepared parts or components to protect from dust and debris. The majority of scratches you will incur during the assembly of painted, plated or polished parts will be from wiping the dust off those parts, rather than from rubbing two parts together.

Again, we cannot emphasize enough that you cover any prepared parts or components to protect from dust and debris. The majority of scratches you will incur during the assembly of painted, plated or polished parts will be from wiping the dust off those parts, rather than from rubbing two parts together.

No Mess Anti-Seize

It is always a good idea to apply some anti-seize lubricant to any bolts that may need to be removed at any time in the future. The lubricant prevents seizing, but more importantly it guards against corrosion. The hot tip here is to use the lubricant that comes in a tube. We have all used the big jar that comes with the application brush built into the lid. It is sloppy, and in the final assembly stages you want to avoid such a mess. Buy the lubricant that comes in a tube. Application is more precise and eliminates making a huge mess.

It is always a good idea to apply some anti-seize lubricant to any bolts that may need to be removed at any time in the future. The lubricant prevents seizing, but more importantly it guards against corrosion. The hot tip here is to use the lubricant that comes in a tube. We have all used the big jar that comes with the application brush built into the lid. It is sloppy, and in the final assembly stages you want to avoid such a mess. Buy the lubricant that comes in a tube. Application is more precise and eliminates making a huge mess.

Put A Sock On It

Your skin can also be a contaminant when it comes to prepared finishes. While assembling all the chrome components on Chromzilla’s chassis, Jesse Greening donned these “Advanced Greening Inspection Gloves” to protect the chrome from fingerprints. The gloves are available through any industrial glove supplier, under the simple name of white inspection gloves. They are both thin and soft, allowing full function of your hands and fingers. The gloves cover just your fingers and hands, with no restriction to your wrist. By using the gloves, especially with chromed items, there will be less cleaning after handling and assembly, thereby protecting the surface one more step. Rubber gloves work well to protect your hands. In the final assembly mode, you should be more concerned with protecting the surface.

Your skin can also be a contaminant when it comes to prepared finishes. While assembling all the chrome components on Chromzilla’s chassis, Jesse Greening donned these “Advanced Greening Inspection Gloves” to protect the chrome from fingerprints. The gloves are available through any industrial glove supplier, under the simple name of white inspection gloves. They are both thin and soft, allowing full function of your hands and fingers. The gloves cover just your fingers and hands, with no restriction to your wrist. By using the gloves, especially with chromed items, there will be less cleaning after handling and assembly, thereby protecting the surface one more step. Rubber gloves work well to protect your hands. In the final assembly mode, you should be more concerned with protecting the surface.

Mask It

Some of the best protection for painted surfaces comes from 3M in the form of a masking sheet. While painters have used this masking sheet to layout flames and graphics, builders have discovered that it works great to protect finished surfaces as well. Areas such as the running boards can be protected from legs moving over them while working inside the interior. The masking sheet does not move around or fall off when touched, yet is easily removed when the work is done. Drop cloths can scratch the finish when they move around under your body or legs. Other areas you should use a masking sheet for is over fenders when working under the hood and around the trunk when working inside it

Some of the best protection for painted surfaces comes from 3M in the form of a masking sheet. While painters have used this masking sheet to layout flames and graphics, builders have discovered that it works great to protect finished surfaces as well. Areas such as the running boards can be protected from legs moving over them while working inside the interior. The masking sheet does not move around or fall off when touched, yet is easily removed when the work is done. Drop cloths can scratch the finish when they move around under your body or legs. Other areas you should use a masking sheet for is over fenders when working under the hood and around the trunk when working inside it

Stage The Large Components

Large components such as a rearend assembly should be staged very near where the installation will occur. Again, the less you have to handle components, the better. Here, Jesse Greening placed the chrome quick-change for Chromzilla where it could be lifted directly into place. Make note again, that a cloth was used under the assembly for added protection to the chrome finish.

Large components such as a rearend assembly should be staged very near where the installation will occur. Again, the less you have to handle components, the better. Here, Jesse Greening placed the chrome quick-change for Chromzilla where it could be lifted directly into place. Make note again, that a cloth was used under the assembly for added protection to the chrome finish.

JUST USE COMMON SENSE

The best advice is to use as much common sense as you can. Provide as much protection to the finished parts as possible. And, do not rush the process. Taking your time to do it right the first time will save more time than you can imagine in the long run. Patience is a virtue when the final assembly begins. If it takes two hours to properly install a component, that is much better than taking an extra six hours to touch up or completely repair the component, and still face installing it.

These are only a few tips we picked up while visiting two of the many great shops building award-winning hot rods. It would be a safe statement to say that many of these came from making a mistake sometime during prior efforts. We can all learn from each other’s mistakes along the way, so share yours with a buddy.