PART 1: How To Choose The Fuel Pump And Injectors That Are Right For You

After working long shifts and weekends, it’s payday and the time has come to enjoy your hard-earned cash. You stroll into the tuner shop and lay down some money on that turbocharger you have been dreaming about buying. Gotcha! Now your system is complete.

You’ve spent a lot of money buying components for your turbo system and now you’re ready to install everything and go boosting, but what about the fuel system? The fuel system is a critical component of any engine setup, regardless of its aspiration. Since the automotive engineers have yet to develop an engine that operates entirely on air, we have to combine air and fuel to make power. There are, of course, various forms of fuel used in engines; but in the interest of simplicity we’ll stick with the common petroleum-powered engine to which everyone can relate.

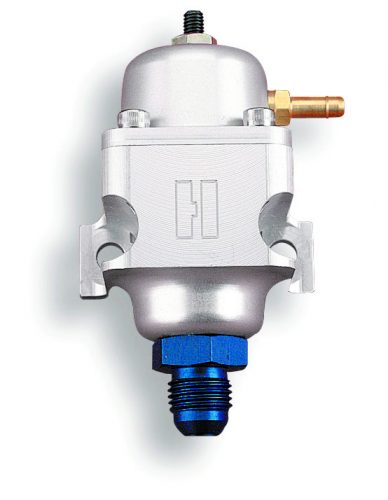

The breakdown of a typical fuel system found in most common vehicles is pretty simple in terms of layout and function. A standard fuel system is comprised of a reservoir (or as it’s commonly called, fuel tank) and a fuel pump that delivers fuel through a feed line to a fuel filter. From there the fuel travels to the fuel rail(s) where injectors introduce fuel to the combustion chamber. Excess fuel that doesn’t enter the engine returns to the fuel tank after passing through a fuel pressure regulator. This system is called a return-style fuel system, as fuel circulates through the system and back into the tank.

Sounds simple, right? Well, that’s just the mechanical side of things. An engine control unit (ECU) orchestrates everything and monitors all the engine parameters, such as coolant temperature, manifold air pressure, throttle position, exhaust gas emissions, engine timing, knock sensors, idle air control and crank angle. We’ll touch upon all of this in greater detail in Part 2 of this article next issue, but for now we’ll crawl before we walk. Let’s start with a basic understanding of components such as fuel pumps, injectors and regulators, and how to choose the proper-sized component for your application.

The ECU takes all the parameters given by the sensors and makes the necessary adjustments in order to make the engine run properly while maintaining a balance of low emissions, power and fuel mileage. It’s easy to see why some old-school enthusiasts want to avoid electronic fuel injection like the plague, but it doesn’t have to be viewed as anything really complicated. After all, it’s easy to understand the basic concepts of fuel management.

Until recently, the return-style fuel system has been used; however, now we are seeing more vehicles like the Honda Civic and Toyota Celica coming from the factory without fuel returns. This does throw a monkey wrench in things when building or tuning an engine for high-performance applications, although today’s enthusiasts adapt easily and are armed with more knowledge than ever.

What you need to know is how to research and select the right components to allow you to reach the level of performance that you desire for your application. As with many things, there are various methods that can lead to the same result in the end. Everyone that’s reading this article has a vehicle in a different state of tune, so we can’t just share some general info and hope that everybody reads between the lines and figures out what they have to do to achieve their goals. Therefore, we’ll start from the beginning, which is the easiest and most inexpensive upgrade that can be performed: upgrading the fuel pump.

If you are planning on installing a nitrous oxide system or a form of forced induction, an aftermarket fuel pump will outperform your existing pump in terms of volume and reliability. This is especially true if your vehicle is over 10 years old. For $150 you can’t go wrong with this added security. A well-fed engine is a happy engine.

Unless you have a Japanese super car such as a Toyota Supra, Mazda RX-7, Mitsubishi 3000GT VR-4, Nissan 300ZX or some other exotic, you should consider upgrading your existing fuel pump. Now, before you head to the auto parts store, you are going to have to figure out how large a pump you require for your engine.

There are two factors that should influence your decision: flow and pressure. Most enthusiasts focus on the pressure aspect of fuel systems by purchasing adjustable fuel pressure regulators and modifying the pressure. You rarely hear about fuel flow—and we’re not talking about upgraded fuel rails, either. This is a critical area. If there is insufficient flow, a lean condition may result despite increased fuel pressure. So how does one choose the proper fuel pump? By using a little bit of mathematics and brake-specific fuel consumption (BSFC).

BSFC is the formula that is used for calculating fuel flow. The units that are used are as follows: pounds-per-hour per horsepower. As a rule of thumb, a gasoline engine will have a BSFC of around 0.40 to 0.60. A lower BSFC is more desirable because the engine will be more efficient. For example, this formula would be used on an engine that produces 350 hp with a BSFC of 0.45 to determine the proper fuel pump:

(350 x 0.45) + (350 x 0.45 x .25) = 157.5 + 39.375 = 196.8 lb-hr

Thus, based on the BSFC formula, the engine requires a fuel pump with a flow rating of at least 196.8 lb-hr.

Thus, based on the BSFC formula, the engine requires a fuel pump with a flow rating of at least 196.8 lb-hr.

With an engine that’s equipped with a turbocharger or supercharger, the fuel pressure is critical because the demand for fuel increases as the manifold pressure increases. This occurs as a result of the large amount of air that is being introduced to the combustion chamber. For example, an engine that is seeing 25 psi of boost will demand approximately 68 psi of fuel to prevent a lean condition. In most situations, this would be too much to expect from a stock fuel pump because fuel flow decreases as fuel pressure increases. Running high boost on a stock fuel pump is like playing Russian roulette.

Depending on your vehicle, installation may take anywhere from 30 minutes to an hour to complete. There are a variety of pumps available with a wide range of operating pressures that allow quite a bit of flexibility when designing a system. The best thing to do is to speak with a technical representative from the company that manufactures the pump before purchasing it. By explaining your application, he or she will be better able to direct you to a pump that will work best.

The next areas that are upgraded most often are the fuel injectors. But how do you know which injector is right for you? Knowing how much power your engine will be producing is a good start, but first let’s get a basic understanding of what role the fuel injector plays in the fuel injection system. A fuel injector is designed to allow measured amounts of fuel to be injected into the combustion chamber, which is vital in the production of power. Too large an injector will result in an engine that runs too rich, fouls plugs and idles rough. An injector that is too small will contribute to a lean condition. Having the proper-sized injector is critical.

By using the BSFC formula, we can get an idea as to how much injector you actually require. The formula is relatively simple, once you have all the variables regarding your engine. Let’s assume that the engine that just received the upgraded fuel pump is also in need of injectors. The variables that we’ll take into account are the number of cylinders, projected horsepower output, peak rpm, BSFC and injector recovery time.

Now, remember that our engine is anticipated to produce 350 hp and it’s a four-cylinder engine. We don’t have to worry about the displacement. So, armed with the BSFC data from the fuel pump upgrade, we know that we have four cylinders, four injectors and a target of 350 hp. We can now establish a formula:

HP = 350

BSFC = 0.45

350 x 0.4 5= 157.5

Based on these calculations, the engine will require 157.5 lb-hr of fuel flow. Yes, this is lower than the flow we required from the fuel pump, but we added an additional 25 percent onto the pump for extra insurance.

Based on these calculations, the engine will require 157.5 lb-hr of fuel flow. Yes, this is lower than the flow we required from the fuel pump, but we added an additional 25 percent onto the pump for extra insurance.

Do you remember what was said about using injectors that are too large for your engine and how idle quality can be compromised? Well, injector recovery time plays a major role in this matter. Injector recovery time is exactly what it says, the amount of time necessary to activate or open and release fuel into the combustion chamber.

There are different types of fuel injectors, such as mechanical injectors, side-feed injectors and conventional top-feed injectors. There are also different injectors for petroleum (gas) and alcohol, as well as high impedance and low impedance. Sounds complex, doesn’t it? It doesn’t have to be.

Let’s assume that our engine runs on gas and we are using low-impedance injectors. Low-impedance injectors typically measure in at approximately 2 ohms and tend to be preferred in high-performance applications because of their faster response time. Low-impedance injectors are more flexible due to the fact that the pulse width can be regulated down lower than high-impedance injectors. The low-impedance injectors also have a lower recovery time of 1.3 milliseconds. However, this isn’t to say that low-impedance injectors are the only way to go, as each type of injector has its place in every application. The best thing to do is consult with a technician regarding your application. Also, different engine management systems—stock or otherwise—may or may not be able to operate a particular injector, while others can control both types.

So what do we know so far? Our vehicle has a four-cylinder engine with four low-impedance injectors that have an impedance of 2.0, power that peaks at 7,000 rpm, and a BSFC of 0.45. We can now begin to determine the proper size injector for our engine. A few additional terms will be introduced at this point: Total Fuel Flow Requirement (TFFR), Uncorrected Injector Size (UIS), Available Injection Time (AIT), Injection Recovery Time (IRT) and Maximum Duty Cycle (MDC).

HP x BSFC = TFFR

TFFR / number of injectors = UIS

60,000 / 7,000 rpm = AIT

(AIT – IRT) / AIT = MDC

UIS / MDC = required injector size

Now that we have a formula, let’s plug some numbers in:

TFFR = 350 x 0.45 = 157.5 lb-hr

UIS = 350 / 4 = 39.37 lb-hr

AIT = 60,000 / 7,000 = 8.571 ms

MDC=(8.571-2.0)/8.571= 0.7666

Required injector size =

39.37 / 0.7666 = 51.35 lb-hr

Now that we have the proper-sized fuel pump and fuel injectors, it will be easier to make a reliable and powerful engine program. Consider this as the foundation upon which the rest of the components will be built.

Now that we have the proper-sized fuel pump and fuel injectors, it will be easier to make a reliable and powerful engine program. Consider this as the foundation upon which the rest of the components will be built.

In our next issue, we’ll cover aftermarket fuel computers such as stand-alone engine management, plug-and-play solutions, and other fuel-related electronics. We’ll also break down some of the crucial sensors that are involved in keeping your engine running properly. Stay tuned for Part 2.

By

By