Manufacturers

Performance enthusiasts are a funny bunch. They all seem to agree that “as much as possible” is the correct answer when asked, “How much power do you want?” But they certainly

disagree about the best way to get there.

When you lift the hood of your ’05 to ’07 Mustang and engage the prop rod, do you feel a little shortchanged? Well, Steeda Autosports has developed a billet hood strut kit designed to replace those clumsy prop rods.

Sound is something that every car guy considers at the top of his or her list of what is important to their ride. Take, for example, the stereotypical sport compact driver. He or she typically has a huge muffler or mufflers and corresponding exhaust tip(s) that make those cars sound as if they are going 100 mph, even when cruising at slow speeds. We Ford guys know that good sound on a real performance car is also important, but we also know that sound must be backed up with corresponding performance.

Improving your new Mustang doesn’t have to be an arduous affair. You’re supposed to enjoy working on your car, RATHER than dreading getting off work because you “have” to wrench on the Ford. With that attitude in mind, we recently spoke with Al Kamhi, of Control Freak suspensions, to get his advice on what enthusiasts could do to further the concept of upgrading a Mustang in just an hour or two. But there’s a catch: the upgrade had to make a real difference in the car’s performance.

Until the early ’70s, trucks were raw workhorses, and they rode high and hard. They were fundamentally designed to work hard. Overly simplistic suspensions were stiff but built to last. These trucks hauled loads around the farm and into town, carried work materials to jobs and even home goods and foodstuffs, much like the wagons of old. They performed their jobs well and for a long time.

When Chevrolet introduced the LS engine, many clever and effective innovations were incorporated to simplify operations and reduce engine weight and overall dimensions. An integral part of these new technologies was a compact serpentine belt system designed from the start to lower frictional losses, which in turn improved belt strength and longevity.

When it comes to performance, there is one steadfast rule: All the good air that goes into making horsepower must eventually find its way out. This means that adding all the cool camshafts, intake manifolds and even superchargers to help improve airflow into the motor will be useless (okay, maybe not useless, but certainly much less effective) if the motor is not able to rid itself of the exhaust. Cork up a serious performance motor and watch it struggle and gag on its own exhaust fumes.

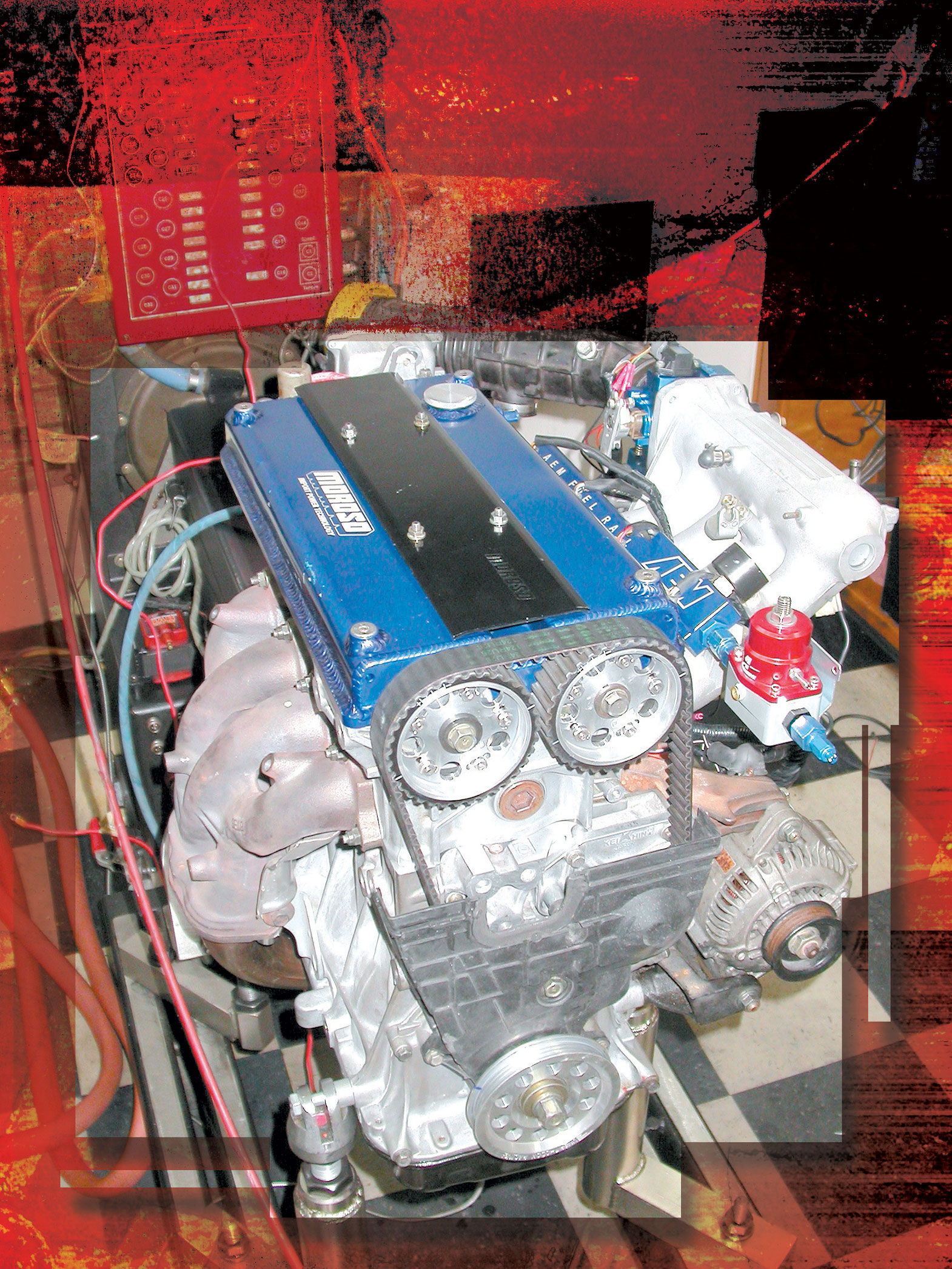

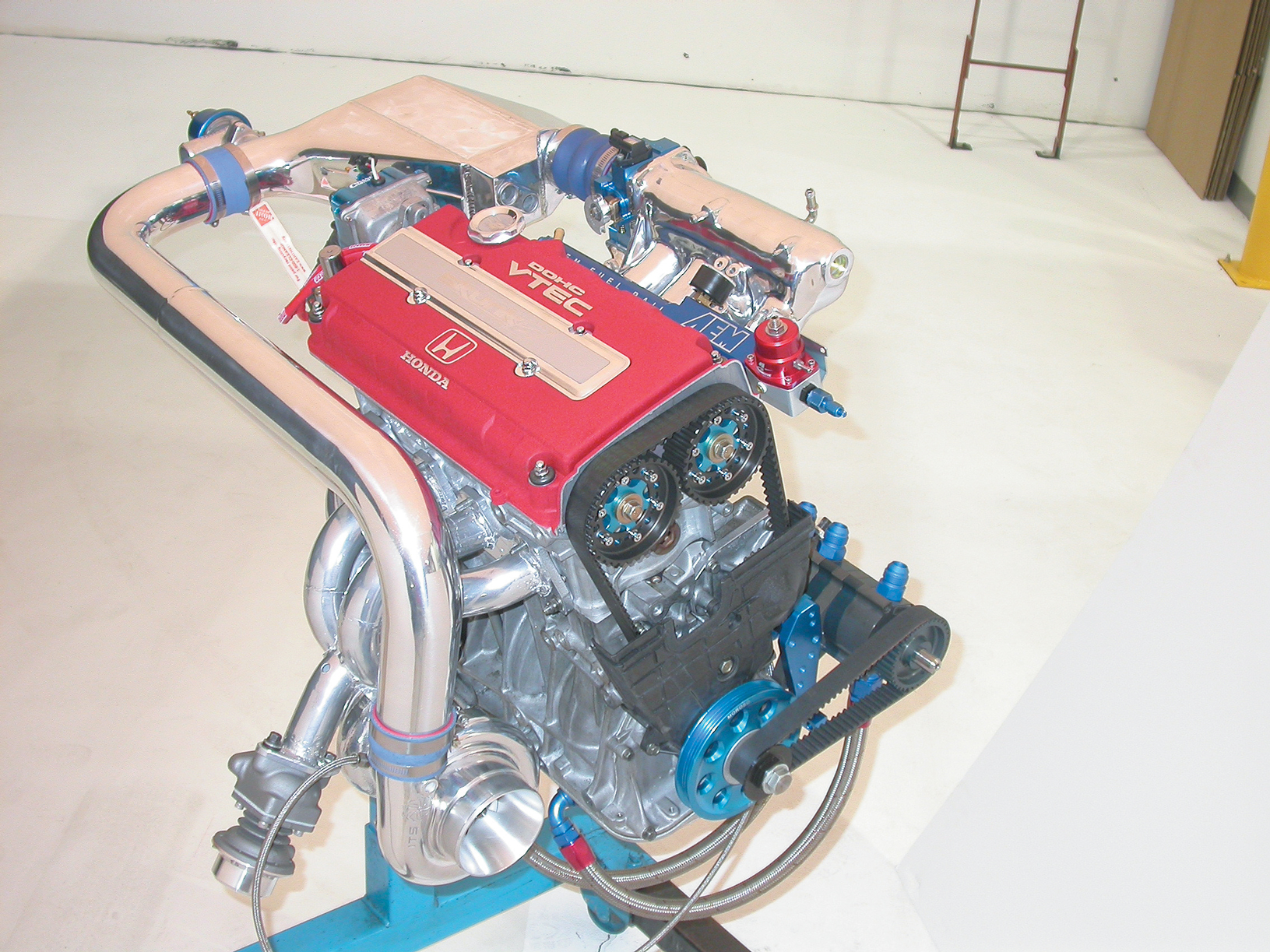

We all know and love the Honda/Acura B-series motors—and for good reason. They have been and continue to be the mainstay of the sport compact performance market. Sure, the new K-series motors are making headway with more and more performance pieces and they look to succeed the B-series once the supply of used motors becomes available in the quantities (and pricing) currently enjoyed by the B-series. But for now, Civic, CRX and Integra engine swappers, not to mention the horde of those originally so equipped, have made the B16A, B18A/B, B18C and B18C5 the performance Honda motors of choice.

Replacing the rear suspension arms is something of a Mustang tradition, and the S197 platform is no exception. Wheel hop is proving to be something of a problem on these vehicles, and Modular Mustang Racing has the solution in the form of new lower rear control arms for the ’05 Mustang.

Previously, we detailed the buildup and dyno test of a 475hp turbo B16A (“Boosted B-Series,” p. 50). Designed for street use, the turbo B16A represented what could be accomplished by combining an efficient normally aspirated motor with the benefits of turbocharging. By taking an already healthy normally aspirated motor, we had a head start to producing big power once we upped the boost pressure with our Innovative T04E-46 turbo. But what is necessary to take power to the next level?