Engine

There are few modifications that can be made to an engine that can give both increased performance and better fuel economy. In these days of increased gasoline prices (nearly $2.50 per gallon), fuel mileage is an important consideration for vintage trucks that owners consider their daily drivers. For many reasons, vintage pickups are becoming not just weekend toys but also weekday workers. And one of the best ways to increase both performance and mileage is with an electronic fuel-injection system.

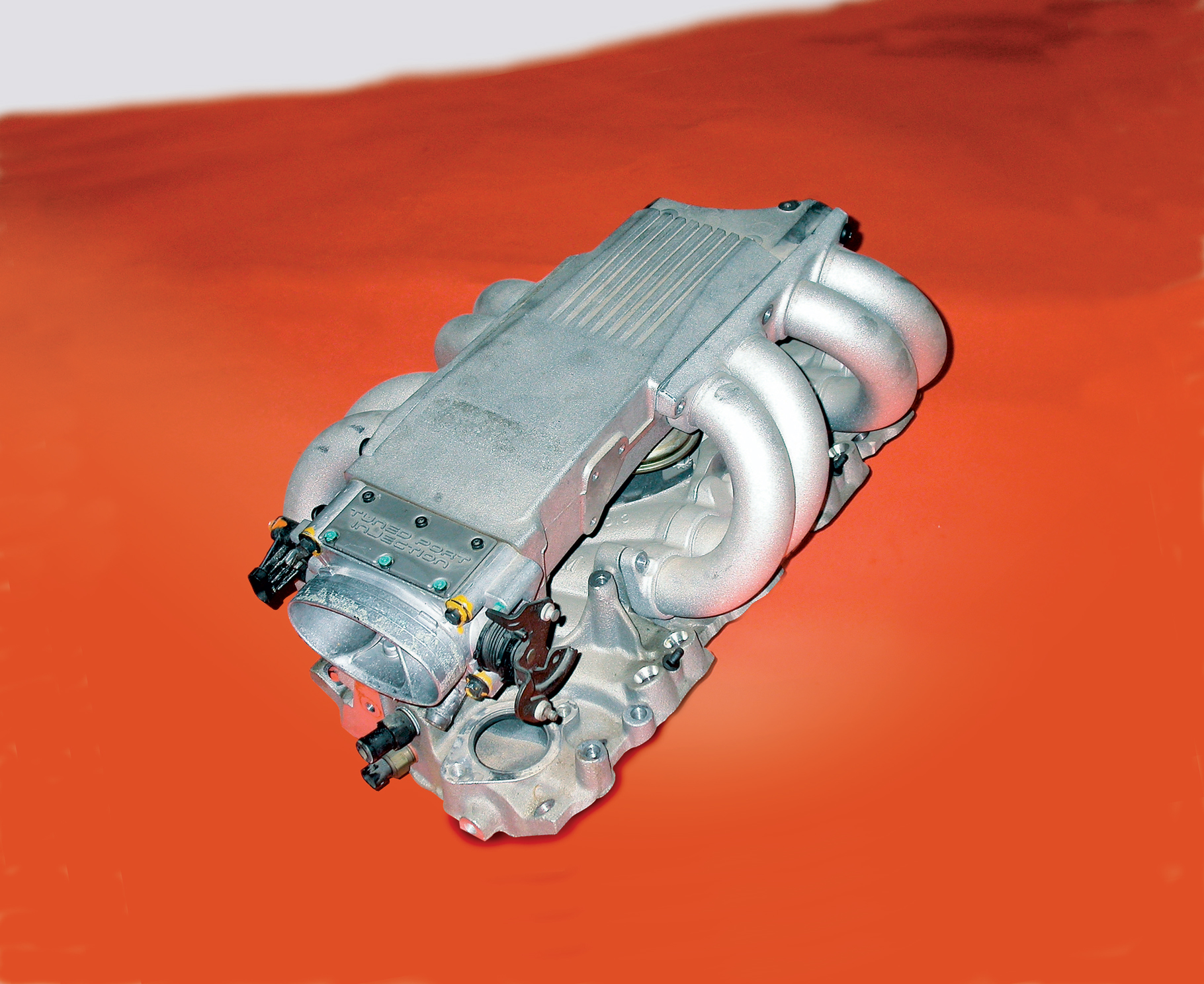

Hot rodders are a picky lot; some want their rides to look as if they stepped out of a time warp, but they also want them to be equipped with the latest of mechanical improvements. Disc brakes, power steering, air conditioning and even full surround-sound stereos and videos are the norm. So it should come as no surprise that the benefits of electronic fuel injection have been fully embraced by those who drive vintage trucks. But with notable exceptions, the look of the fuel injections systems was mostly unpleasing to the eye.

Producing horsepower requires two major ingredients, namely, air and fuel. Of course, the two must be supplied in the correct proportions and at the proper time; but improving power is a simple matter of adding airflow. Naturally, additional fuel will be required once the airflow is improved, but the first item on the horsepower priority list should always be more airflow.

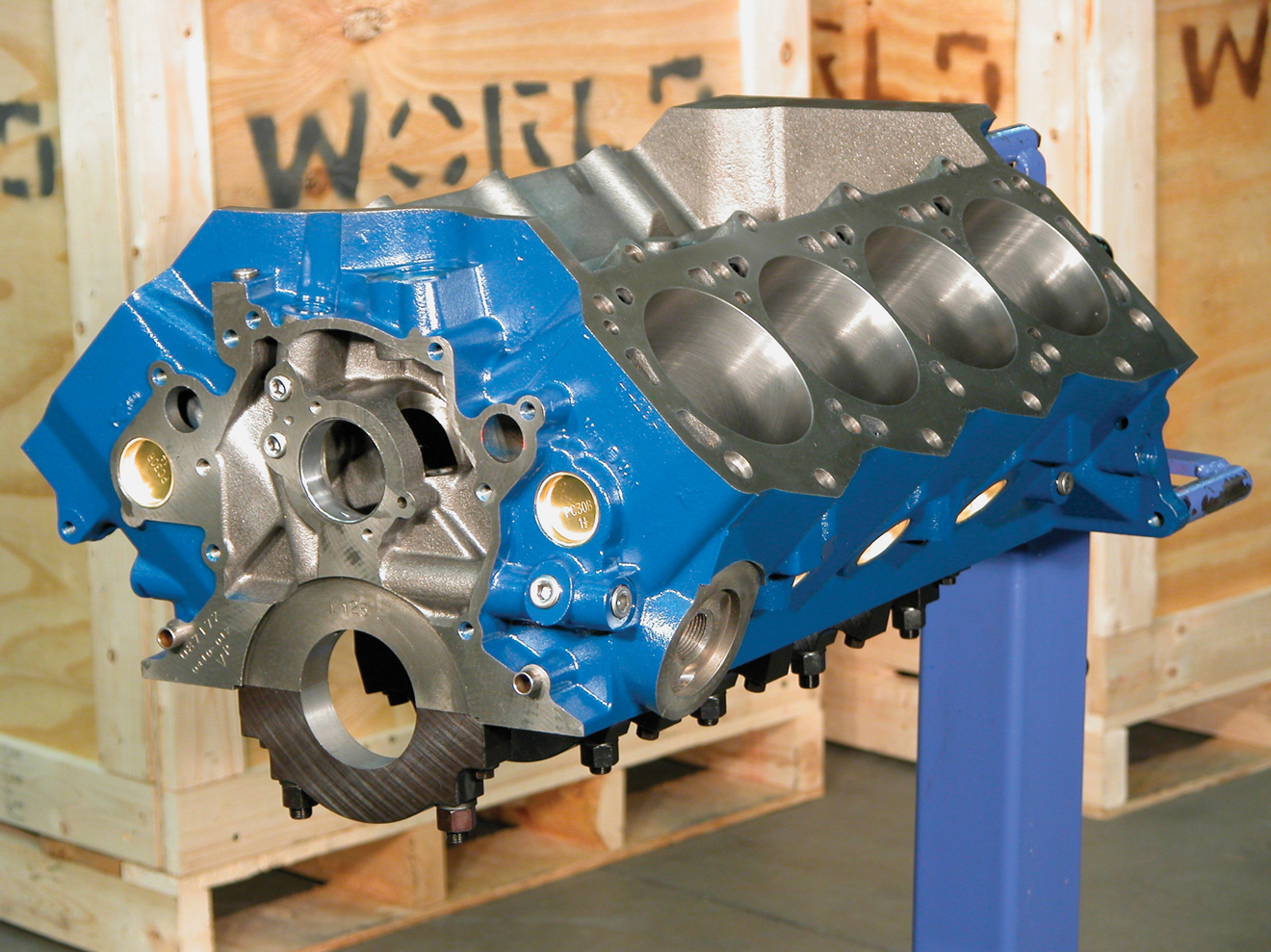

While the small-block Chevy is the popular engine choice for many enthusiasts, many are now relying on a Blue Oval heart for their performance bodies. With its link to Ford, the original body manufacturer for many of the classic cars we see today, the small-block Windsor-style Ford engine offers several advantages. When compared to Chevy, the lack of firewall clearance for a number of Chevy engine swaps is due to the rear distributor position of the engine. The front-mount distributor position is the more logical place to drive the distributor and the oil pump. Not to mention, it’s much more convenient.

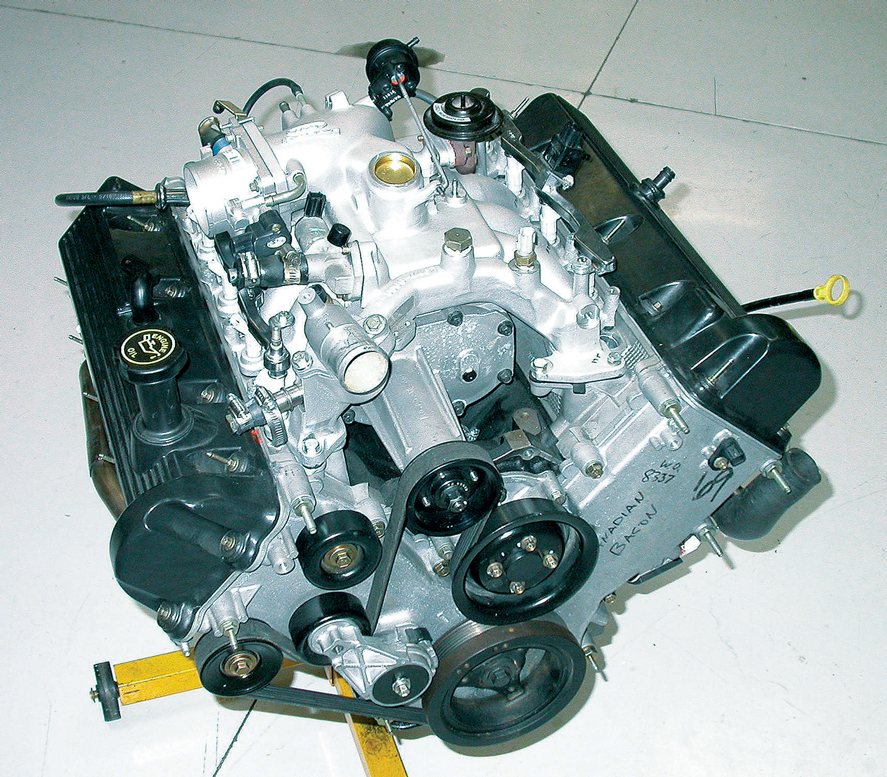

One of the most misunderstood performance components on any engine has to be the camshaft, or camshafts in the case of our overhead-cam 4.6-liter Ford engine. The difficulty is only compounded when you add forced induction to the mix. From an anatomical standpoint, the camshaft can be likened to the brain, as the cam profile determines how effectively (when and where) breathing takes place.

Time and time again, our advice to those interested in learning about stout-running engines is that it’s the total combination that makes it all happen—considering, of course, that components are prepped, cleaned and assembled as if in a “clean room.”

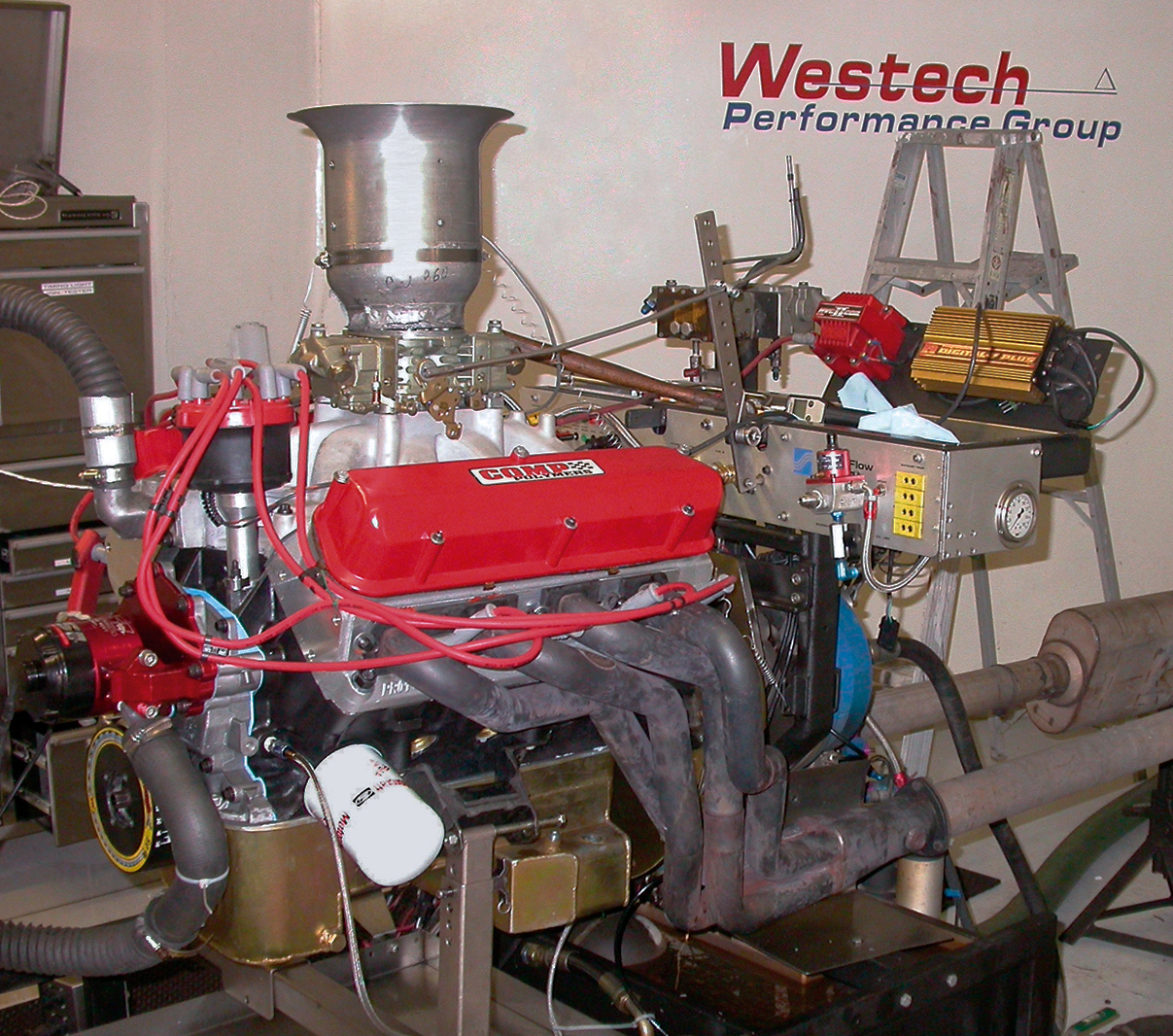

We first wrote about this 565-cubic-inch Dart “Big M” engine, equipped with Dart Big Chief II Pro Stock-type aluminum heads, back in our October ’04 issue. The engine builder was Quarter Mile Performance in Chatsworth, California, and at the time, we called it “possibly the world’s most powerful four-barrel big-block.” It produced 1037 horsepower at 7200 rpm and 806 lb-ft of torque at 5500 rpm–plenty stout by anyone’s standards.

The small-block Chevy has enjoyed a long, happy life. Sure, the current LS1/LS6 version is quite far removed from the original, but thousands upon thousands of little mouse motors continue to provide the sole means of motivation to everything from stationary irrigation pumps to Le Mans-winning C5R Corvettes. Naturally, this list also includes all manner of boulevard bruisers, street stompers and resto rockets. Heck, we’ve even seen little Chevys under the hood of “Brand X” machinery. The continued popularity of the small-block Chevy is not surprising. Take a look at the combination of power potential and parts availability and multiply that by the cost quotient, and you have the makings of a real success story. Add to this equation the millions of project motors just sitting around junkyards throughout the world, and it is easy to see why enthusiasts continue to embrace the mighty mouse motor as the performance powerplant of choice.

Small-block water pumps are common replacement parts and are available at prices that are nearly impossible to beat. However, while getting a brand-new water pump for cheap is great, sometimes you need to keep the one you have. If it’s date-coded, or maybe you’ve installed a chrome steel or an aluminum water pump. You aren’t going to get those at the parts counter. In cases like these, rebuilding a water pump is preferred to buying a new one.