Street Trucks

The Specialty Equipment Market Association (SEMA) Show engulfs Fabulous Las Vegas annually. It brings together the biggest names in the automotive world to show off the latest and greatest, whether it’s new products, amazing custom builds, or the newest trends. TheAutoBuilder is excited to be in the thick of it all.

LS Swaps are extremely popular, and for good reason! ACES EFI makes the swap process super simple with its Jackpot EFI system. Check out this awesome ‘83 Chevrolet Silverado and get the finer points of the Jackpot from Kim and Pete!

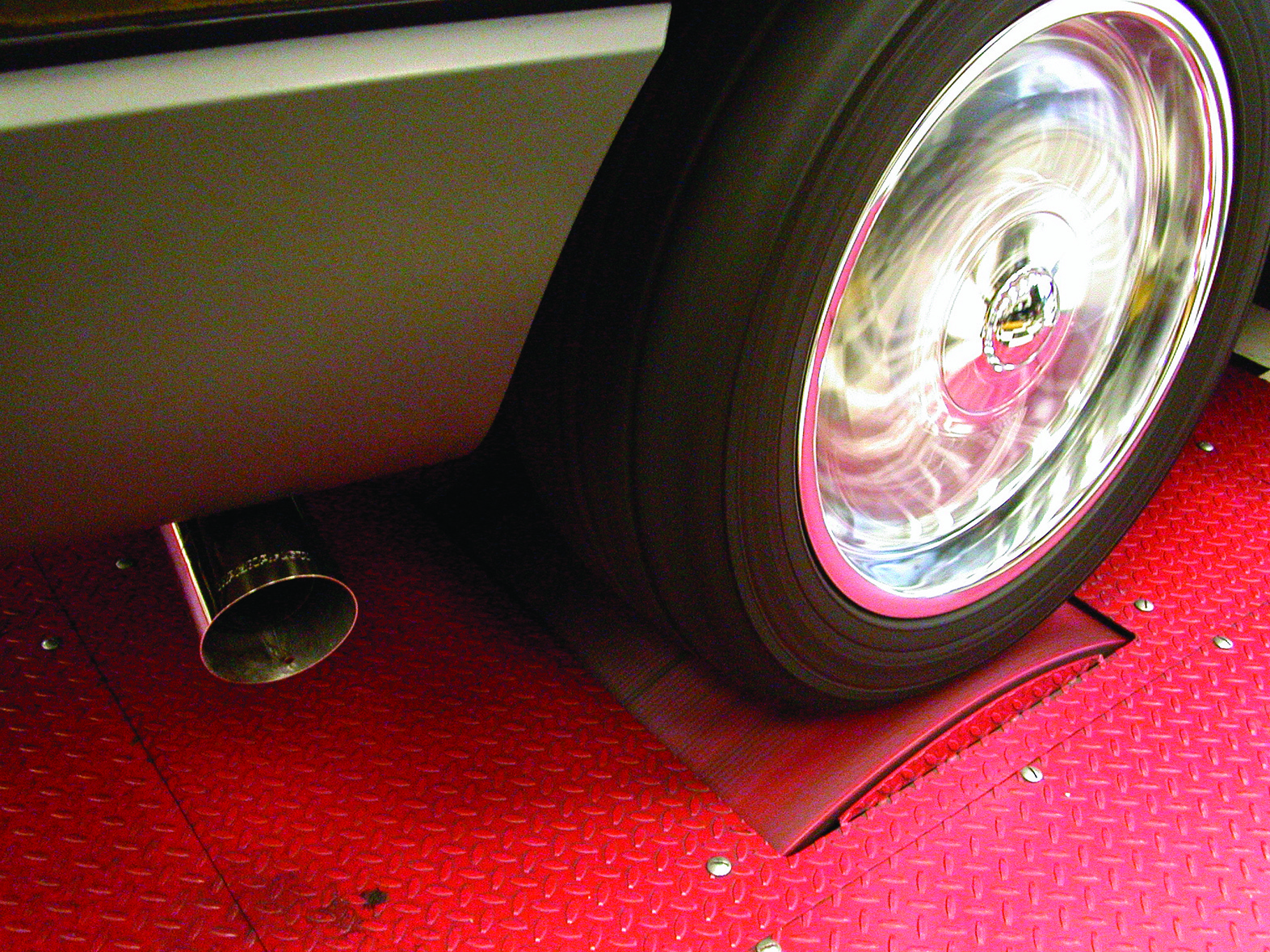

When this ʼ54 Chevy truckʼs owner started building it, he wanted it to be fast and to have a nasty appearance. He always liked the Pro Street style, so that is the direction he decided to follow. He started by ordering a custom back half that was narrowed and set up with a narrowed rear differential with coilover shocks, a Panhard bar and ladder bars. In order to complete the back half, the car was delivered to Dream Cars, where the suspension was installed.

Typically, winter isn’t the time of year when we are thinking about a car’s air-conditioning system…or is it? It’s understandable that we would tend to think about “fixing” the A/C during the dog days of summer, July or August, but once the car is put up for the winter, those hot and humid days are often forgotten. And short of those comfortable windows-down driving months, when we first pull out the car again for the next season, it’s smart to think about giving the A/C system the attention it needs. So, we think this is a great time to present to you troubleshooting highlights so that you can rip into the car and upgrade the necessary areas before the cycle continues.

When building a street rod there are a great many facets of the construction process that go into making the car an award-winning creation. First, there’s planning. The planning of the car can and should include attention to each and every area of the car, from concept to reality. Even the most basic of projects should have the proper planning involved, no matter what the final product might be. Once work has begun on the project, countless hours are generally involved in attending to every detail. From making the many modifications to the chassis to attain the desired drive train, to the matching and mating of the different components together, this becomes an involved process requiring a great deal of skill in fabrication and engineering.

Time and time again, our advice to those interested in learning about stout-running engines is that it’s the total combination that makes it all happen—considering, of course, that components are prepped, cleaned and assembled as if in a “clean room.”

We first wrote about this 565-cubic-inch Dart “Big M” engine, equipped with Dart Big Chief II Pro Stock-type aluminum heads, back in our October ’04 issue. The engine builder was Quarter Mile Performance in Chatsworth, California, and at the time, we called it “possibly the world’s most powerful four-barrel big-block.” It produced 1037 horsepower at 7200 rpm and 806 lb-ft of torque at 5500 rpm–plenty stout by anyone’s standards.

The small-block Chevy has enjoyed a long, happy life. Sure, the current LS1/LS6 version is quite far removed from the original, but thousands upon thousands of little mouse motors continue to provide the sole means of motivation to everything from stationary irrigation pumps to Le Mans-winning C5R Corvettes. Naturally, this list also includes all manner of boulevard bruisers, street stompers and resto rockets. Heck, we’ve even seen little Chevys under the hood of “Brand X” machinery. The continued popularity of the small-block Chevy is not surprising. Take a look at the combination of power potential and parts availability and multiply that by the cost quotient, and you have the makings of a real success story. Add to this equation the millions of project motors just sitting around junkyards throughout the world, and it is easy to see why enthusiasts continue to embrace the mighty mouse motor as the performance powerplant of choice.