Built Like an Old-World Fortress, World Products’ New Windsor-Style Blocks Give Ford Fans an Affordable Alternative to Stock

While the small-block Chevy is the popular engine choice for many enthusiasts, many are now relying on a Blue Oval heart for their performance bodies. With its link to Ford, the original body manufacturer for many of the classic cars we see today, the small-block Windsor-style Ford engine offers several advantages. When compared to Chevy, the lack of firewall clearance for a number of Chevy engine swaps is due to the rear distributor position of the engine. The front-mount distributor position is the more logical place to drive the distributor and the oil pump. Not to mention, it’s much more convenient.

None of this has anything to do with the popularity of the Mustang or its ever-increasing popularity for 5.0 engine buildups. The small-block Ford is quickly becoming the engine of choice, and it makes perfectly good sense to put a Ford engine in a Ford vehicle when dealing with something other than the Mustang. World Products applies its vast engine block-building experience to make the options as wide as possible. Considering that the Ford block has the tightest cylinder banks of the common three small blocks, it helps to keep the average Ford engine shorter than the Chevy engine.

The Windsor engine’s relatively thin bulkheads and lifter valley lead to block cracking, usually through the lifter valley. This could be described as a catastrophic failure of the cylinder base. Typically, this is an issue with high horsepower-producing engine combinations that employ considerable doses of supercharged or turbocharged boost and/or nitrous. This much we do know.

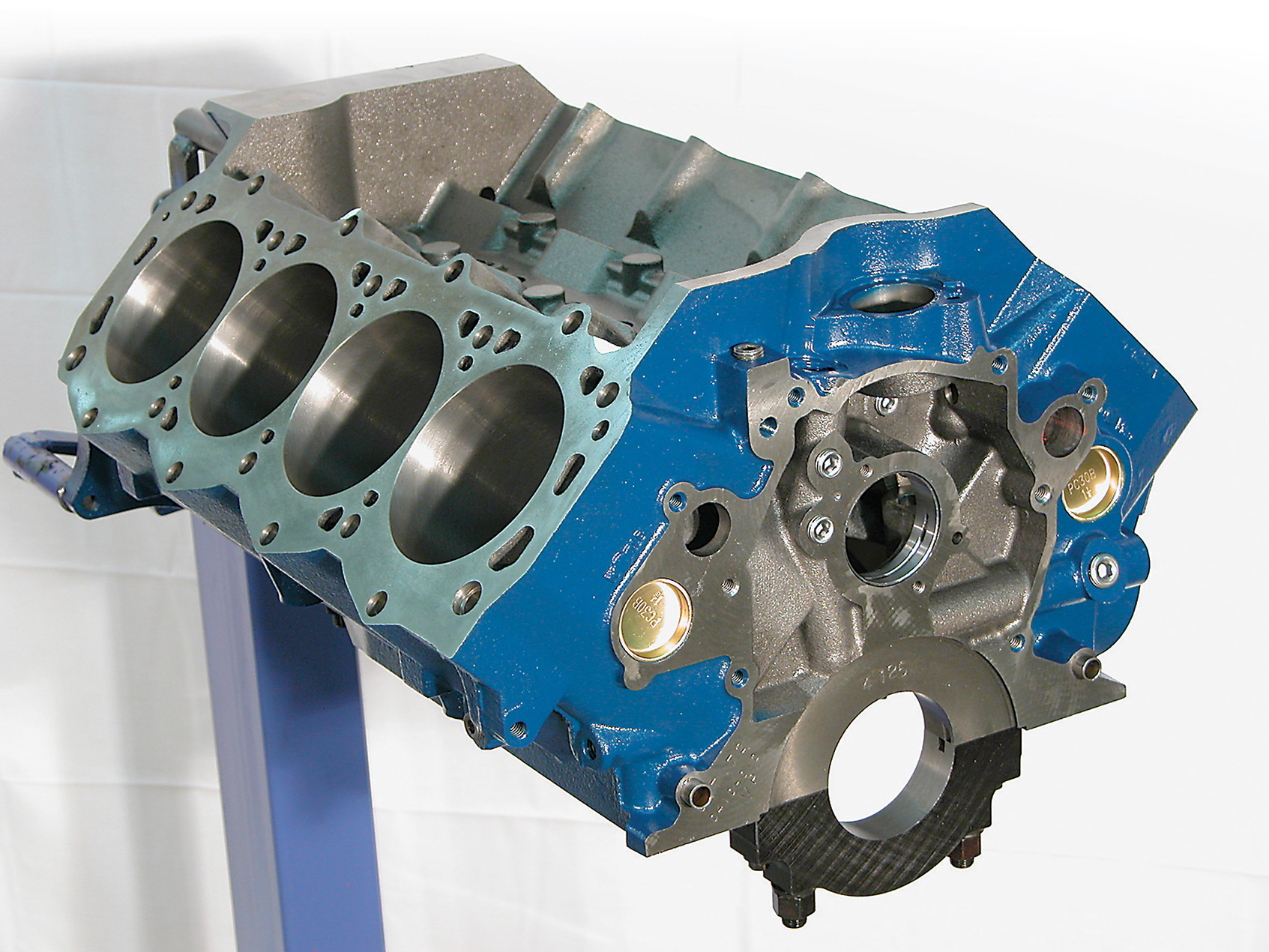

A bare 302-style block weighs slightly over 130 lbs, which is great if you’re trying to keep the pounds off your ride. However, it indicates that there’s not much meat on the Windsor’s bones. World Products recently introduced a new Windsor-style cylinder block called the Man O’ War. It adds about 60 well-placed pounds of iron strength to the 302-style block. And while it’s not the first aftermarket Ford-style block on the market, the roughly $2,400 price tag undercuts the alternatives by about a third. This makes the Man O’War block attainable to most every enthusiast, not just well-funded race teams.

World Products in Long Island is headed by longtime racing engine builder Bill Mitchell. He’s known more for his outstanding Chevy-based work than his Ford work, but the company currently offers several popular Ford-style cylinder heads. And while small- and big-block Chevys have driven World Products’ success—including the popularity of the Motown small-block and the infamous Merlin big-block engines—they all feature World Products’ own cylinder case castings. These blocks are externally identical to GM’s original blocks, but they carry extra material in strategic areas, such as the front and rear bulkheads. This material allows for larger bore sizes and supports large displacements. For example, World Products currently offers 632-inch Merlin engines and 454-inch Motown “small-block” engines.

That technology and experience get transferred into the production of World Products’ Ford-type blocks. In addition, Mitchell has incorporated a recently developed machining process that, he says, helps make the blocks much more affordable. As with the Chevy blocks, building a better Ford cylinder case started with dissecting a regular-production 302 block to see where the help was needed. Mitchell admits that he wasn’t all too familiar with Ford engine failings when the project started, so he dug deep into the shortcomings of the cylinder block. He was helped by some very influential members of Ford-based NASCAR racing organizations.

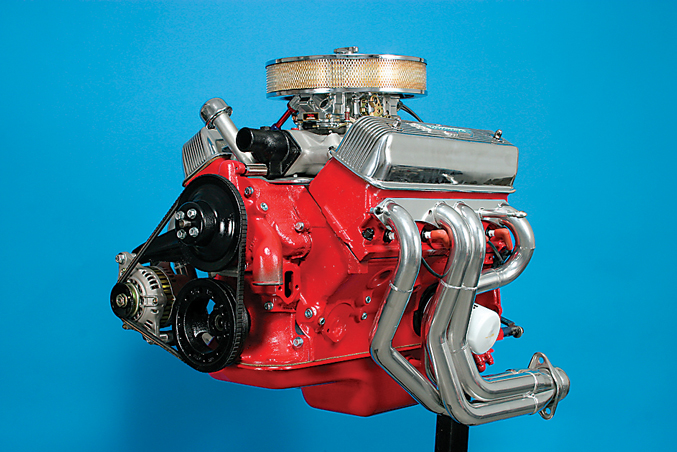

According to Mitchell, the team sliced open a NASCAR engine to identify all the areas that needed improvement. They developed a “wish list” that would create the perfect Ford block, including improved oiling, cooling, added strength and rigidity (block integrity). “We transferred everything on the [list] into this new block design,” says Mitchell, who also made sure that, like his other block designs, the Man O’War was bolt-on friendly. “We took the measurements of every accessory hole and mounting pad, whether [they were] used in recent production engines or not, and transferred them to the Man O’War,” he says. “You can bolt on any aftermarket or Ford accessory—it all fits.”

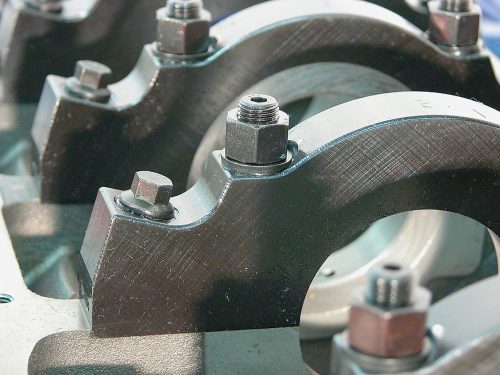

The Man O’War is a definite improvement from the original-equipment block. It includes bulkheads that are about a full inch thicker than stock, along with clearly visible material added to each cylinder bank. Also, splayed, four-bolt mains with billet steel caps and 1/2-inch inner fasteners are the standard hardware.

World Products offers the Man O’War in four deck heights, including 8.200 inches, 8.700 inches, 9.200 inches and 9.500 inches. The 8.200- and 8.700-inch decks are 302-style blocks, while the two taller decks are 351-style blocks. The minimum deck thickness is 0.600 inch.

A “C” version of the 302-style block is available with mounting positions for the oil pump and distributor in the same location as the 351 blocks. With standard Ford 302 blocks, interference with the oil pump keeps maximum displacement to about 347 ci; the Man O’War “C” blocks will permit a maximum 375ci “302.”

These new blocks come with unfinished 3.990-inch or 4.115-inch bores, which must be finished to 4.000 inches and 4.125 inches, respectively. With a 4.250-inch stroke (the largest the blocks can take) in a tall-deck block, a 460 small block is available. Actually, the cylinders will safely bore out to 4.200 inches. That, along with the 4.250-inch stroke, permits a small-block displacement of 470 ci in tall-deck versions.

To help maintain adequate lubrication throughout—a challenge with production Ford blocks—the Man O’War has priority-main oiling, 1/2-inch oil passages and cast-in bosses for lifter cross-feeding. The block is also designed for production-type roller cams, so you can bolt on all typical Ford EFI equipment.

At 189 lbs in the short decks and 227 lbs with the tall decks, the Man O’War will add weight to a Ford engine combination, but the iron is used in all the right places. Nevertheless, Mitchell tells us an aluminum version of this block is scheduled for the near future. So, for those of you who are on a tight vehicle diet or front-to-rear weight bias balance, a solution is in the works.

Currently, however, the iron Man O’War blocks offer a stronger, more rigid foundation for all new and rebuilt engine combinations. Also, they are the foundations for a new line of World Products’ short-block assemblies and Ford crate engine packages. We’ll outline those outstanding crate engine packages in an upcoming issue, so stay tuned. It’s a whole new world for us Ford guys, at least those of us who want to keep the distributor in the front where it belongs.

Article Sources

World Products

http://www.pbm-erson.com/catalog/world-products

631/737-0467

51 Trade Zone Court Ronkonkoma, NY 11779